Tool Grinding Capability Key To Medical Success

Making toold for surgeons is critical to the succesful use of orthedic implants. This Indiana shop succeeds because of its dedication to quality and application of the right machine tools for the job.

NG Instruments, a contract manufacturer in Warsaw, Ind., has grown its reputation and its business by consistently doing what it does best: making surgical cutting tools and instruments, such as drills, taps and reamers to customers’ design. “That’s our core competence, and that is what we do to grow our business,” says Tony Nicholas, president and co-founder of the company. As he puts it, “We build the tools that help put people back together.”

The strategy seems to be working. NG has recently expanded its manufacturing floor space, building its capability to deliver precision tools to the demanding medical market.

The tools that the company makes are used to drill, tap or ream a hole, sometimes all three depending on the surgery to be performed. For example, drills for trauma surgery are used to drill the hole for a bone screw to prevent any further damage to the patient. The company also builds joint replacement tools for hips, knees and shoulders—mostly drills and reamers. Drills are used to remove most of the material, and the reamer brings the hole to size and to a particular shape to match the implant.

NG Instruments also builds spinal tools used in back and neck operations, mostly drills and taps. The spine is very critical, so the tools have a built-in stop to control depth. The OAL and length to the stops must be held very tight, typically within 0.005 inch.

Finding The Right Machine

“I took a little different approach than perhaps others have in terms of business strategy,” Mr. Nicholas says. “We started out concentrating on producing drills. Then we went to making taps. Then we were asked to make reamers. At that point, I looked around for a precision grinding machine builder to partner with. I knew about what we do, but the builders know machine tools.”

So, he decided to test the capabilities of a few grinding machines. “I made blanks and sent them to several builders to see if they could produce the tools I needed. I saw cycle times from each, and I actually bought another brand cutter grinder,” Mr. Nicholas admits. “I had it ordered, and it was supposed to be on the way. But the leadtimes were being extended more and more. Cutter grinder builder Anca came through with a machine immediately, so I ordered it as well as a second one and had both up and running before the other machines would have reached customs.”

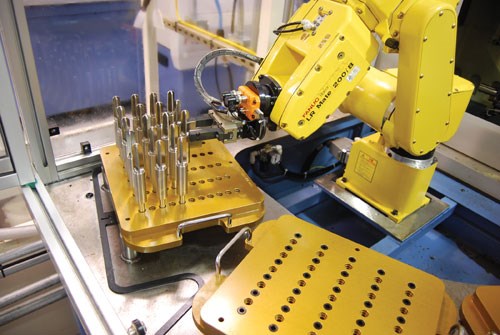

Today, NG operates five of the company’s model TX7 machines (two with Fanuc robot loaders or other loading automation) and four RX7s (two with integrated automated loaders).

The company planned in 2007 to use the RX7 to produce smaller tools and some threading. Again, it gave Anca the tools to make, and it was successful in demonstrating the machine on those tools. According to Mr. Nicholas, the RX7 was just the right size, options and power to produce the tools, including pointing, allowing us to produce the tools complete in one chucking. With the loaders, NG can operate the machines untended.

“We invested in and use these machines primarily to make larger diameter medical tools (mostly in stainless steel) which often have long flutes,” Mr. Nicholas explains. “So we have developed clever ways to support the material in the chuck. Many of our tools are heavier on the cutting end, such as a shoulder reamer, in order to create holes of a certain diameter; the shank end that goes into the medical tool driver is a much smaller diameter. Our solution uses the Anca collet system, but we have modified it to successfully hold the tools.”

Processing From Barstock

The company produces the tools from barstock, first turning the blanks, heat treating, centerless or cylindrical grinding with CBN wheels, fluting and straightening. Tolerances are usually in the 1- to 2- tenths range and sometimes tighter on diameters, depending on the tool being made.

All tools are stainless steel with hardnesses ranging from 38 to 55 Rc depending on the grade of stainless. Lot sizes range from single-piece custom jobs to 250 pieces at the high end. Average lot size is 130 pieces.

There are generally 16 to 24 operations to build a tool. NG typically starts with a 12-foot stainless bar, turns a blank, mills a driver, heat treats, straightens, grinds flutes or threads, deburrs, polishes, EPs, bead blasts, laser etches, passivates, inspects and ships. Degreasing operations between each step prevent oil contamination. Cleanliness is obviously a critical specification.

The other key component is paperwork. “Everything is documented and controlled, and after we finish the part, work must be audited and kept in perpetuity. A lot goes into building anything medical,” Mr. Nicholas explains. At the customer, the tools, primarily reamers, are kitted in sizes from 6 mm to 32 mm in 0.5-mm increments.

Every machine tool in the shop is less than 5 years old. The facility, recently expanded, is clean and well lit. The process for the medical cutters is fully integrated: incoming material is carefully checked, machining is driven from NG’s extensive CAD database, production is designed around cells and manufacturing and inspection departments have the same ability to measure the product. All secondary operations are completed in-house.

Upgrading For Faster Production

One of the reasons NG Instruments continually upgrades its capability is that it has found that new machines offer more speed because of the processing power of new-generation controls. Using a single brand of machine has advantages as well.

“We can put the same program from an older machine on a new machine and take out 20 to 30 seconds from the cycle time just from faster machine moves,” Mr. Nicholas says. “With the Ancas, for example, we can control the gap distance so we can race up to the tool and start machining. On-board dressing lets us keep close control of our wheel geometries so we get extended production without

interruption.”

Another benefit to the software for the shop is that it allows different in-feed rates per pass and a variable feed rate along the length of a flute. This optimizes material removal, which reduces both the grinding cycle time and wheel wear, and therefore, lowers the cost of the finished tool.

Software Advantages

For a shop like NG, flexible software that can accommodate its production mix and special tool specs is a key to productivity. The combination of Anca’s simulation and programming software allows NG to be much more creative and experimental with designing new and sometimes exotic tools.

Users of CIMulator3D would be familiar with features such as tool measurement, cross sectional viewing of tools, wheel collision detection and complete machine model simulation. But the software also includes features that improve the efficiency of the grinding simulation process. The result is a smoother machining process.

Machine idle time for setting up new tool programs is eliminated by taking the programming step offline to perform the simulation. On a separate PC, tool geometry, machine movement and grinding parameters are all confirmed before the first tool is ground. The simulated tool path is then imported directly into the CAM process. While programs are developed offline, machines are free to run production.

The simulation software includes collision detection to indicate where elements other than the desired grinding wheel are hitting the tool or machine, further reducing setup time and cost associated with scrap parts. Its cycle time estimator allows NG to more quickly optimize grinding cycle setup while offline and helps in production planning and quoting.

Because it can streamline a process offline while it continues production on the floor, NG also has the ability to use the cutter grinders for prototype work. Jason, a company programmer, can work out the program at his desk, show the customer the solid model, confirm the design is what they want, and then upload the program and make parts immediately.

NG Instruments has become good at optimizing the process. Part of the advantage this software brings to the task is the ability to recognize and produce complex tool geometries. According to Mr. Nicholas, other machines may not recognize the shape or may process it slowly. “Our machine’s control has the processing power to handle the complex shapes we work with.”

Value Added

“With the Anca simulation package, we can show our customers what the machine can do,” Mr. Nicholas explains. “Just because you can draw it, does not mean it’s producible. We can modify a new part in development and prove that a tool can work and can be produced. And with our customers in the area, we can present to them the real article for their inspection in very little time.

“With the help of this software, I can also make suggestions as to what could make a better performing tool and send a jpeg image of what it would look like. In that way, it really helps us add value to the jobs we do,” Mr. Nicholas says.

“I like the way it programs and especially the ability to program offline. You can get everything lined up ahead of time, then upload a program, making starting a new job smoother,” he adds.

The Machine

Power and speed make the TX7+ a good choice to do the tool grinding at NG. The machines feature a 49-hp, 10,000-rpm spindle, an automatic wheel changer, optional auto-loading system and a 3,000-rpm headstock.

To produce a different range of tools, the machines perform a complete change-over of the wheel pack, coolant system, workholding collet and pallet in less than 3 minutes. For the TX7, wheel packs and corresponding coolant manifolds are prepared off-machine and quickly exchanged to grind a new tool.

The direct drive, high-speed (3,000 rpm compared with 200 rpm, typically) work head (A axis), allows users to include cylindrical grinding operations in the tool grinding process without changing the setup, and to fully grind stepped or tapered blanks to the final tool. OD grinding for reamers and drills is also common at NG. This means tools can be produced complete in a single setup.

Considering the complexity of the tools the shop produces and that they must exhibit a perfect finish, completing a tool in a single handling is a significant claim and a big advantage for the company.

“One of the tool types—a cannulated tool—is gundrilled through its length before we grind the flutes,” Mr. Nicholas says. The bore through the tool accepts a 1/16-inch diameter rod that is used to help guide the tool in use, preventing it from walking. The tools are 10 to 21 inches long—grinding fully accomplished on the ANCA TX7+.

“This grinder also has quick moves and has the horsepower we need to do the work. The machines are flexible and give us the ability to handle the complex geometries we need to make, and consistently,” he says. For NG as well as most cutting tool manufacturers, cost is a big issue and is getting bigger.

“Since these cutting tools are a commodity item, you must be able to make them quickly,” Mr. Nicholas says. “They are used once and thrown away. Although offshore competition is trying to come into the market, we have been able to fight it off with automation, a skilled workforce and an ability to move quickly. We try to keep our leadtimes at 4 weeks or less.”

The Future

“It makes sense from my point of view to stick with a vendor as long as it is taking care of its customer, and Anca is taking very good care of us, “ Mr. Nicholas explains. As we grow, I plan to continue with the company. The operators are already trained and can go from machine to machine. One of our employees we got right out of high school, and now he is in charge of the setups on the machines.

“Today, when it can be difficult to find employees that are trained or willing to be trained, younger employees seem to like these machines. They seem intuitive to them. When the young people walk onto our floor, they see a good-looking machine that is not dirty and is driven by graphically rich software.”

Related Content

Automation in the Alps: Studer AG Unveils New Grinding Concepts

Studer AG, member company of United Grinding, held its annual press conference at its Swiss Alps location earlier this month to announce its new automatic loaders to accompany its existing grinding machines as well as other offerings and automation features.

Read MoreTooth Flank Grinding Technology Minimizes EV Drive Noise

Drives for electric vehicles require gear components with tight tolerances and excellent surface finishes. Even minimal ripples in the surface of tooth flanks on shafts and gears can cause interference noise in drive performance.

Read MoreEmag Grinding Solutions Provide Precise Gear-Profile Grinding

The G 160 and G 250 gear-profile grinding machines provide short chip-to-chip times, intelligent axis concepts as well as thermal and mechanical stability.

Read MoreStar Cutter Grinding Machines Improve Uptime, Throughput

Tru Tech grinding machines are designed to achieve high accuracy for high precision and micro components in numerous industries including medical, aerospace and electronics.

Read MoreRead Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.jpg;maxWidth=300;quality=90)