Training–Perform, Document, Manage Effectiveness

The need for training in our shops and businesses is indisputable. No one graduates from high school with the skills and knowledge to perform as a journeyman machinist. If your company is ISO 9001:2000, Section 6.2.2 describes the records of training that must be maintained; if you are TS16949:2002, the requirement is found in Section 6.2.2.2. If you are FDA Medical Device-compliant, 21CFR, Part 820.25 describes the training requirements for your company.

The need for training in our shops and businesses is indisputable. No one graduates from high school with the skills and knowledge to perform as a journeyman machinist. If your company is ISO 9001:2000, Section 6.2.2 describes the records of training that must be maintained; if you are TS16949:2002, the requirement is found in Section 6.2.2.2. If you are FDA Medical Device-compliant, 21CFR, Part 820.25 describes the training requirements for your company.

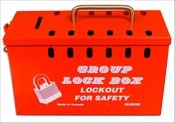

The Occupational Safety and Health Administration (OSHA) has countless regulations, many of which require an effective training program. Some of the most obvious and applicable to precision machining shops include Control of Hazardous Energy (Lockout-Tagout), Hearing Protection, Flammable and Combustible Liquids, Personal Protective Equipment, Hazard Communications (HAZCOM), Powered Industrial Trucks (forklift operator training) and Mechanical Power Presses.

Examples of two lesser-known regulations requiring formal training are Dip Tanks (1910.94 (d)(9)(i) and 1910.94 (d)(9)(vi)); and Portable Fire Extinguishers (1910.157(g)(1), (2), (4)). There are also a host of additional training requirements that appear in other standards (such as ANSI) that have been adopted by reference into OSHA, Part 1910. These are also mandatory in the general industry sector.

A resource for the safety training mandates by OSHA can be found in the General Industry Section, pages 20 through 55 of “Training Requirements in OSHA Standards and Training Guidelines,” available as an Adobe pdf at: www.osha.gov/Publications/osha2254.pdf.

Knowing the topics that employees need to be trained on is only the first step. Other critical steps include performing the training; documenting the training; and auditing the effectiveness of the training. Ineffective training in the safety arena puts your employees at risk. Ineffective training in quality systems or job procedures puts your entire business and your value chain (both customers and suppliers) at risk.

The management challenge. Our military forces are constantly training so that their personnel are fully capable at a minute’s notice. There is no second-place winner in military affairs. Similarly, the challenges that our employees face in the execution of their daily work leave no room for failure. Getting a diploma should not be the end of education and professional growth.

Still, many of us struggle with training issues because we don’t see the difference between training for competence versus training for awareness. Many of our systems are set up to document evidence that training took place, but at the expense of perhaps missing the point of whether or not that training was effective. An employee’s signature on a training log is weak testimony after the inspector or auditor has asked that employee a relevant question and received a shrug as an answer.

Training for competence. Training for competence can be easily designed since an objective measure of success is evident (that is, the ability of the trainee to perform some action). Training for competence can be structured in a purpose-objectives-benefits format.

For example, Purpose—to safely de-energize and lock out this machine; Objectives—to know where the lockout switch is, how to shut down prior to lockout, safely de-energize and lock out, and prove that equipment is de-energized; Benefits—to understand that uncontrolled energy from electricity, moving tools or powered equipment can cause injury.

Presenting is not an effective means of training for competence. Presenting is a means that can be used to successfully create awareness. However, it is the hands-on, on-location, using the actual equipment, demonstrating and correcting behavior that creates successful training. While presentations can effectively create awareness, if there are no other reinforcements, that awareness will diminish over time.

Using job descriptions and existing work instructions will enable you to ensure that employees receive training on the important aspects of their jobs. Use training as an opportunity to re-evaluate the job and tasks being performed. Do not use it as simply another milestone to be passed on the road to compliance. Every training contact is an opportunity to continuously improve both the trainee and the organization.

Documenting training is important in today’s world of quality and management systems that require evidence of performance. Sign-in sheets or log sheets are granted almost holy status by trainers and quality managers. However, when employees fail to answer or understand an auditor’s question—despite a hand-signed log sheet attesting to their training—it calls all of the organization’s paperwork into question.

An observation report prepared by a trainer or supervisor is the truest tool for effective training. This report should plainly state whether the employee was observed correctly performing the task or if there is a need for retraining. It is the feedback of this observation step that locks in the trained behavior and assures the quality and effectiveness of the training. What effective process do you know of that does not include a feedback loop?

Management’s additional role. Management has one more role in this training cycle besides identifying the need, providing the means and assuring that the training works through documented observations. Management must hold itself and the entire organization accountable for not only the task of training, but also the expected, desired outcome of the training.

To accept training as a mere formality is failure to care about the organization and its people. Accepting paperwork rather than looking at hard evidence of effectiveness of the training is where many managers miss the point. While the quality systems focus on records and record keeping, they are not the goal. Development of competent employees is the goal.

It’s not the papers in the files; it’s the performance of the people. Managers have to observe performance to standards. That way, an outside auditor will not be the first to audit your employee’s performance, and identify that they might not have “got it.”

Related Content

Emerging Leader's Problem-Solving Skills Cool Down a Hot Project

This 2023 Emerging Leader developed a product in response to a call for help from Yamaha that was a huge hit in the snowmobile industry when it hit the market in 2010. In fact, it is now a common product that most snowmobile OEMs have implemented.

Read MoreVideo Tech Brief: CNC Screw Machines a Solution for Overcoming Labor Shortages

CNC screw machines can exceed job shop productivity and enable manufacturers to overcome perpetual employment gaps.

Read MoreStrengthening Manufacturing Workplaces Through Active Listening

A good strategy to weather the storms of manufacturing market upheavals and unpredictable factors is to commit to continuous, active employee listening.

Read MoreThe Value of Aligning Efforts to Promote Manufacturing Careers

Successfully building the next generation of manufacturers requires a team effort between employers, educators and parents. Each of these three groups has a tremendous impact on young people’s career decisions. Without the support of all three, we are unlikely to bridge the skilled labor shortage that threatens the future growth of our industry.

Read MoreRead Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More