While many of the recent college graduates (more than 25 percent) are unemployed and heavily in debt for degrees that did not assure their employment, young people with solid high school math ability can get immediate employment in precision machining. Almost every shop owner that I have spoken with has openings for people with skills or who are willing to learn. On-the-job training is supplemented with coursework at community colleges and online courses. With many employers offering help with tuition, a future of indebtedness is not an issue. Having a job and income while others do not is a great “head start,” especially when one is on a career path where pay increases as skills increase. And you can pay as you go for the college courses you need.

Precision Machining: Great Work and Great Pay

PMPA serves companies in the NAICS 332721 precision machining industry. According to the 2010 census, our industry produced about $12.7 billion worth of products. Parts for medical devices, automotive and aerospace, food service and appliances are just a few of the markets served. PMPA surveys usually 100 shops to track hourly shop wage rates nationwide in the industry. Wages are surveyed by job, geographic area, and average and median.

Using the U.S. average for 2002 through 2012, Swiss (non CNC) wages are up 40 percent from $10.15 to $14.26; multi-spindle CNC wages are $11.59 to $14.58, up 26 percent; and four axis and above CNC wages are from $10.42 to $13.35, up 28 percent. Considering that we have “lost a decade” in manufacturing, these numbers show growth and are above the consumer price index increase, as well.

These wages are significantly above minimum wage levels, and compared to not working while in college, provide a great head start with lifetime earnings. But an operator position is just the starting point. Why not look at precision machining as a career? What if the operator upgraded his skills to setup operator? How does that look compared with the unemployed college graduate loaded with debt?

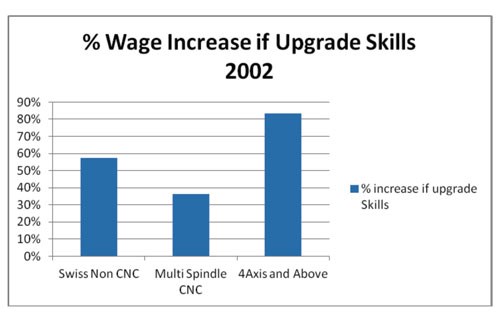

The above graph shows the percent of change in wages between operator pay in 2002 and setup operator pay in 2012. If employees upgraded their skills from operator to setup operator, our data shows the hourly wages increased for Swiss (non CNC) by 57 percent; multi-spindle CNC by

36 percent; and four-axis and above CNC by a whopping 83 percent. And setup operator is just the next step. Some precision machinists further their skills, and go on to specialize as programmers, supervisors, repair technicians or engineers. Additional college coursework is manageable and has a clear ROI when one is already employed.

How Can We Get More Information?

If you have the ability for high school algebra, geometry and trigonometry, you are likely to succeed in the precision machining field. To find training programs in this field, contact your local community colleges and training schools. Tom Olson, an instructor at Milwaukee Area Technical College recently wrote, “We have a lack of people applying for the skilled trades programs. Especially in machining. We could double our enrollment if we had more candidates.” There are openings at schools as well as at employers for people in our advanced manufacturing field.

To find precision machining shops in your area, go to the PMPA website and search for a manufacturer: short.productionmachining.com/mheqwoh5. Enter your state to find candidate companies. Call them and explain that you want to know more about a career in manufacturing. Ask to visit, and come prepared to see the latest technology and people happy to be making a difference making parts that save lives, keep people safe, or help people to get where they want to go.

PMPA Vice President Darlene Miller led the creation of “Right Skills Now,” a program to help math-qualified candidates get the skills needed for entry level CNC operator positions. Right Skills Now has programs in several states:

rightskillsnow.org

To find other schools offering training in precision machining, check out the following links:

MATC: short.productionmachining.com/7gh345s1

LCCC: short.productionmachining.com/vt2x2c1o

Nationwide list sortable by state:

short.productionmachining.com/a8hiij3a

Nationwide list:

short.productionmachining.com/nnsfyo4r

A career in precision manufacturing can be taken as far as you want to take it. Getting skills as an entry level employee will serve you well as you take the next step to become a setup person. Further coursework at the community college level (while you are working and earning a wage) can help you prepare for additional career growth in engineering, quoting, supervision or management. Why start your life at the bottom of a debt hole where there are no assurances for a job and the only guarantee seems to be large amounts of college debt?

Gaining skills, having a job, and having a positive career trajectory are available right now with a career in precision machining. It’s something college students thought they were getting, but many are finding they didn’t. The economics of an immediate job, and your family values regarding assuming large amounts of debt, should convince you that in today’s economy, a career in manufacturing may be the best decision that you can make. Grow your skills, grow your education, and grow your earnings. Grow your career.

— Precision Machined Products Association