Employee Ownership Guarantees Commitment

Rable Machine Inc., being 100-percent employee owned, has empowered the workforce to take seriously the quality of their products and emphasize on-machine probing as part of the company’s ongoing efforts toward more efficiency.

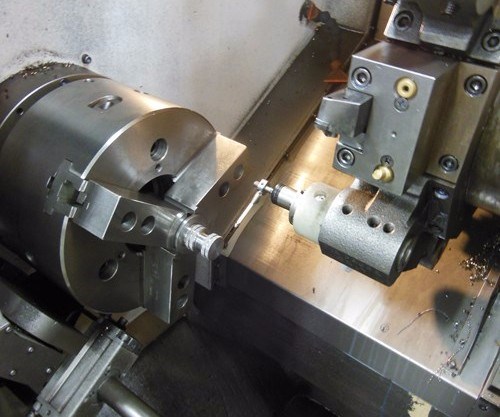

While adding to cycle time and being limited to certain applications, on-machine, in-process probing helps to ensure precision for extremely close-tolerance part features

A business cannot thrive without committed employees, and one way to guarantee that is through employee ownership. Rable Machine Inc. out of Mansfield, Ohio is 100-percent employee owned, which has empowered the workforce to embrace new technologies and implement a number of creative solutions to production issues. They take seriously the quality of their products and emphasize on-machine probing as part of the company’s ongoing efforts toward more efficiency.

These efforts have included a move to a 53,000-square-foot facility that has allowed room to expand lean manufacturing and cellular machining strategies, including implementing the Micronite knowledge-based SPC system from High Tech Research out of Deerfield, Illinois. These systems allow operators to quickly enter dimensions without wading through multiple pages of hard copy inspection control plan. This provides assurance to newer operators and prevents operator over-management.

For a look at how Rable persists in looking for new ways to improve production in all its areas through the support of a dedicated group of employees, read Chris Felix’s feature “Probing for Quality.” Read the article here.

Related Content

-

Manufacturing Skills Training: Virginia Martinez and Laiken Carrillo

Roles of Women in Manufacturing Series: A precision machining career starts with skills. Virginia and Laiken share their journey and how they help prepare the next generation.

-

Applying a Healthy Approach to Employee Investment

Service Center Metals’ on-site health center offers its employees and their families free same-day health care and, in return, the employer is gaining many benefits including a healthier workforce and attracting potential employees.

-

The Value of Aligning Efforts to Promote Manufacturing Careers

Successfully building the next generation of manufacturers requires a team effort between employers, educators and parents. Each of these three groups has a tremendous impact on young people’s career decisions. Without the support of all three, we are unlikely to bridge the skilled labor shortage that threatens the future growth of our industry.

.jpg;maxWidth=300;quality=90)