Everybody Talks About the Skills Gap, But Some are Doing Something About It

One recent effort to help change the skills gap was hosted by Okuma America at the company’s headquarters in Charlotte, North Carolina.

Students get a first-hand look at several cutting demonstrations on state-of-the-art Okuma CNC machine tools.

The shortage of skilled young people to fill increasing demand for good, manufacturing jobs is no mystery. How to increase exposure to manufacturing in the 21st century is the challenge.

One recent effort to help change the skills gap was hosted by Okuma America at the company’s headquarters in Charlotte, North Carolina. Area students were invited to visit and see first-hand career opportunities for engineers, machine tool operators, programmers and service professionals. They also toured the facility and were able to see several cutting demonstrations on state-of-the-art machine tools and to speak with Okuma sales and technical professionals in the CNC manufacturing industry.

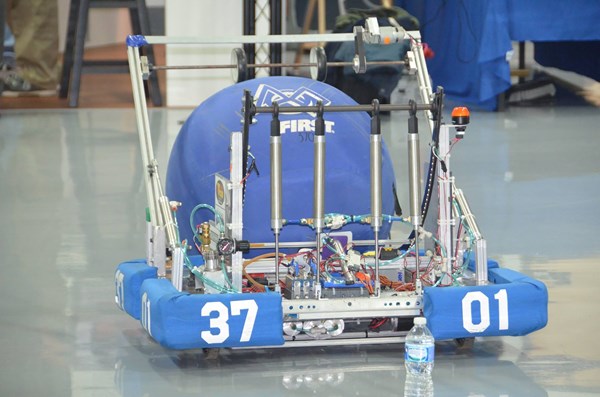

As part of the company’s dedicated STEM development in the area, Okuma sponsored the Royal Robotics Team from Piedmont Community Charter School, who attended and demonstrated its award winning robot to the Okuma members. The Royal Robotics Team is a member of FIRST (For Inspiration and Recognition of Science and Technology) and participates in the annual FIRST Robotics Competition.

This is a winning strategy for other companies interested in doing something positive in their communities to help close the manufacturing skills gap. Ongoing, Okuma is hosting several student-related, educational events during the upcoming year, including a special event in October to celebrate Manufacturing Day.

The industry needs to reach out to change people’s minds about manufacturing opportunities for young people.

The Okuma sponsored Royal Robotics Team from Piedmont Community Charter School demonstrates its team robot.

Related Content

-

Strengthening Manufacturing Workplaces Through Active Listening

A good strategy to weather the storms of manufacturing market upheavals and unpredictable factors is to commit to continuous, active employee listening.

-

Video Tech Brief: CNC Screw Machines a Solution for Overcoming Labor Shortages

CNC screw machines can exceed job shop productivity and enable manufacturers to overcome perpetual employment gaps.

-

CNC Machine Shop Employment Positions to Consider Beyond Machine Operators

Many machine shops have open machine operator positions to fill. But does it make sense for shops to also seek automation engineers, IT managers and assembly personnel?

.jpg;maxWidth=300;quality=90)