From Unemployment to Essential Worker — Adapt to Thrive

“If you want something new, you have to stop doing something old.” - Peter Drucker

In my early days as a laborer in the steel mills, I was laid off with considerable regularity. In fact, I was asked by my congressman to testify as an expert witness on unemployment, as I had more time on layoff than on the job. But I stuck with manufacturing, as I loved knowing that the steel we were making was needed to make the autos, appliances and everything else that modern living required.

One of the lessons I learned though, from each and every layoff, was the need to grow my “portfolio,” reach for more responsibilities and train to gain new skills. Later, in university business classes, I recognized that I had lived Peter Drucker’s advice, “If you want something new, you have to stop doing something old.”

Unemployed or Essential?

As of this writing, almost 20 million people (19.8 million according to a report out of Drexel) find themselves unemployed in the leisure, hospitality and retail trade. That is a decline of 60% — and one-third of that is due to businesses shutting down. Remaining employees saw a 10% reduction in weekly hours, according to the report.

Meanwhile, the precision machining industry has fared quite differently as our performers were designated as essential workers due to the critical nature of the components we produce for lifesaving and other advanced technologies.

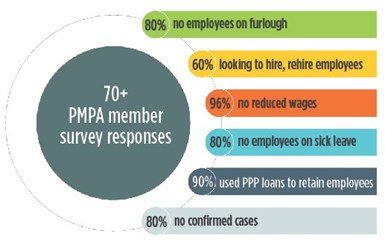

Compare the results of our latest PMPA member survey (70+ respondents) to the facts from the Drexel study cited above:

- 80% of PMPA member shops had no employees on furlough

- 60% of responding shops are looking to hire, rehiring furloughed employees

- 96% had not reduced wages

- 80% had no employees out on sick leave

- 90% had used PPP loans to retain employees

- 80% had no confirmed cases

The response to the COVID-19 crisis in the U.S. by government, employers and consumers has greatly impacted the evolution of the job market. It’s what evolutionary biologist Steven Jay Gould deemed “punctuated equilibrium.” According to lexico.com, “evolutionary development is marked by isolated episodes of rapid speciation between long periods of little or no change.” In other words, an event that upsets the long-standing equilibrium causes the need for rapid changes in order to adapt to the new unstable conditions. According to the Biology Dictionary, punctuated equilibrium also posits that “…changes that bestow an advantage will be amplified quickly in small populations.”

Adapt and Thrive

Our precision manufacturing shops need talent. With 60% of the hospitality, leisure and retail industry finding itself on layoff, I have to believe that there are talented people from these industries who can bring their experience — serving others, performing important tasks, doing routine calculations and paying attention to details — to find a place in our essential manufacturing, precision machining shops.

If you have a friend or neighbor who you know has a great work ethic, did a great job at their old job and is looking for a chance to get back to work, ask them to consider joining you at your job — where you make the things that make a difference.

If you want something new, you have to stop doing something old. Thinking that restaurants are going to be full again and that wages and tips will be back to normal is probably not the best thinking. Business travel is looking to be stunted for years into the future. Retail traffic is down as disrupted supply chains reduce the reward for shopping, and as risk of infection from in-person shopping continues to be a factor.

At PMPA, we help our members to adapt and thrive. Adapt and Thrive is not our vision, it’s not our mission. Adapt and Thrive is actually what we help our members do. Adapt and Thrive. In the face of the punctuated equilibrium of COVID-19 across our economy, unemployed performers can find an opportunity to do something new, but first they must stop doing something old. There are 80% of PMPA shops that had no employees on furlough due to our designation as essential manufacturers. there are 60% of our shops that are looking to hire or recall furloughed workers; and 96% that had not reduced wages.

COVID-19 was a punctuated equilibrium event across the economy. It is also providing a unique opportunity for former retail, hospitality and leisure workers to Adapt and Thrive by bringing their life skills, talent and ability to perform to our industry where they can make a difference.

Do you want something new? Consider resetting your employment trajectory by investigating opportunities in a local precision machining shop. According to PMPA’s May Business Trends Report, “Sixty-seven percent of respondents (two-thirds) expect employment to remain the same or increase over the next three months.” This is in close agreement with our survey that said, “60% of responding shops looking to hire, rehire furloughed employees.”

The economy and employment markets have been substantially transformed. If you are currently unemployed, transform yourself so you can join the ranks of essential workers in our industry who continue to Adapt and Thrive.

Read More Articles from PMPA:

Smith & Richardson — Surviving COVID-19

Craftsman's Cribsheet: Mechanical Property Tests — Hardness and Hardenability

About the Author

Miles Free III is the PMPA Director of Industry Affairs with over 40 years of experience in the areas of manufacturing, quality, and steelmaking. He helps answer “How?, “With what?” and “Really?” Miles’ blog is at pmpaspeakingofprecision.com; email: mfree@pmpa.org; website: pmpa.org.

Related Content

Roles of Women in Manufacturing: What I Learned

Over 20 women were featured in the Roles of Women in Manufacturing series, which started in January 2023.

Read MoreTurned and Polished Steel Barstock: How It Is Manufactured, How It Impacts Your Shop

Understanding the benefits provided by turned and polished steel barstock and its differences from cold-drawn steel barstock can help you and your team avoid unexpected performance issues.

Read MoreCraftsman Cribsheet No. 128: Why Do Machinists Say Tenths Instead of Ten Thousandths?

In machinist parlance, a tenth is a tenth of a thousandth, not a tenth of an inch.

Read MoreOnshoring Weather Report: Strong Tailwinds!

Onshoring, reshoring, nearshoring: these terms are showing up with increasing frequency in the news and online. But is there evidence that these are real?

Read MoreRead Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.jpg;maxWidth=300;quality=90)