Grinding at the Micron Level

This article looks at how Glebar Co. has applied sliding headstock to its grinding machine and has employed centerless grinding principles to achieve high accuracy and complex geometries to production of very small diameter workpieces.

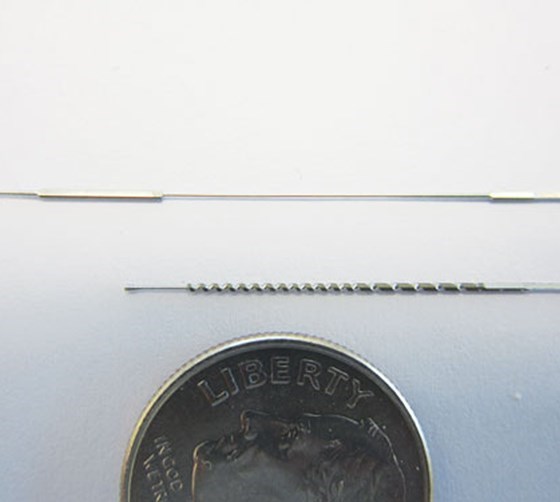

Geometrically complex guidewires used for medical procedures are machined on grinders using a combination of centerless grinding technique and sliding headstock motion for Z-axis travel.

Most of us are familiar with sliding headstock machining used in Swiss-type turning. It’s a proven technology for producing parts that have length-to-diameter ratios that can’t be machined any other way.

This article, “Manufacturing Efficiently at a Micron Level,” looks at how Glebar Co. has applied sliding headstock to its grinding machine and has employed centerless grinding principles to achieve high accuracy and complex geometries to production of very small diameter workpieces.

Manufacturing parts for medical applications, including guide wires, are well within the wheelhouse of this machine’s capability. The micro-grinding machine also has measurement and inspection systems as part of its lineup. Making a part is one thing, verifying what has been made is another.

Click here to read the full article.

.jpg;maxWidth=300;quality=90)