High-Pressure Coolant Improves Profits and Productivity

High-pressure coolant that is efficiently applied to a cutting tool will enable faster, more precise cuts; prevent oxidation of the tooling and workpieces; and prolong the life of a cutting tool.

Unpredictable cutting tool wear or failure has an adverse effect on machining speeds, feeds and throughput. Coolant that is not efficiently applied to the cutting zone is a leading contributor to these problems. However, this can be corrected through proper application of high-pressure coolant delivery, according to Ron Parker, national product manager, LNS Chipblaster High Pressure Coolant Systems.

For milling, drilling and turning, the friction generated by conventional metal machining creates substantial heat where the cutting tool meets the workpiece. By some estimates, 97% of

In this turning application, 1,000-psi coolant is directed precisely at the point of cut for optimum efficiency. (All photos courtesy of LNS Chipblaster High Pressure Coolant Systems.)

energy consumed in metal machining converts to heat. That’s why machinists have always attempted to cool the cutting zone by applying liquid or gas coolants that may be petroleum- or plant-oil-based, water-soluble or derived from animal fats.

The objectives are to:

- Moderate the temperature in the cutting zone to maintain consistency;

- Lubricate the work surface and cutting tool to enable faster and more precise cuts;

- Prevent oxidation of the workpieces and tools; and

- Prolong tool life.

Low-Pressure Problem, High-Pressure Positives

In many cases, though, coolant is delivered at relatively low pressures to the cutting

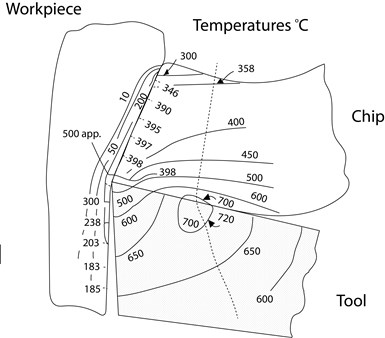

This illustration shows heat generated in a workpiece and cutting tool during machining. Low-pressure coolant delivery can form super-heated steam that prevents the coolant from reaching the tool.

area where it simply floods the workpiece and cutting tool. Unfortunately, because of the heat generated during a cut, this method might produce super-heated steam before the coolant is able to reach the tip of the cutting tool. As a result, little or no lubrication is provided, the temperature is not consistent, and chips are not efficiently evacuated and are recut, thus accelerating tool wear and possibly damaging the workpiece.

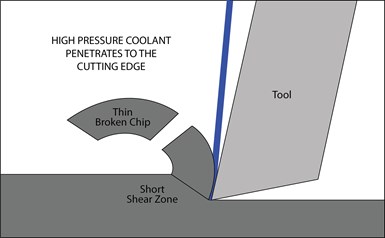

But when coolant is delivered to the cutting zone via pressures of 1,000 psi or higher, the additional force increases localized pressure that eliminates the formation of super-heated steam. Thus, the coolant successfully reaches the tool tip and prevents premature failure because of heat damage.

The high-pressure coolant force does not break chips, rather the cooling of the cutting tool causes the chips to break. Then, the high pressure stream blasts the chips away from the tool, thus preventing damage.

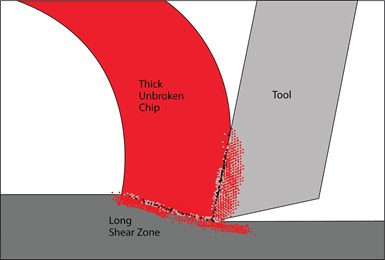

Further, because the chips produced are kept at a cooler temperature, they break much more easily and are quickly evacuated from the point of cut. The force of the high-pressure coolant is not what breaks the chips; instead, it’s the effect of the coolant that shortens the primary shear zone. Therefore, instead of producing long, stringy chips (as is typical with low- pressure coolant), high-pressure coolant produces shorter, broken chips.

Cooling of the cutting tool by high-pressure coolant causes chips to curl more aggressively and break, preventing recutting of chips.

Additionally, the cutting tools can wear at a more predictable rate, making tool replacement far more efficient.

Examples of Improved Cut Data

High-pressure coolant delivery enables machines to cut material more efficiently. One way to measure this is by comparing surface feet per minute (sfpm), which is the number of linear feet that a given point on the cutting tool travels in one minute. For example, 300 series stainless steel has a median sfpm of 325 to 350. With high-pressure coolant properly applied, the same material can be milled at 800 sfpm. Here are other examples.

|

Milling sfpm with High-Pressure Coolant: |

|

|

Aluminum |

10,000 sfpm |

|

Low Carbon Steel |

2,000 sfpm |

|

Medium Carbon Steel |

1,200 sfpm |

|

Stainless 300 Series |

800 sfpm |

|

Cast Iron |

1,600 sfpm |

|

Titanium |

400 sfpm |

|

Inconel |

350 sfpm |

|

Copper |

1,200 sfpm |

In drilling applications, high-pressure coolant helps evacuate chips from the hole and eliminates the vapor barrier that inhibits cooling.

|

Drilling sfpm with High-Pressure Coolant: |

|

|---|---|

|

Aluminum |

2,000 sfpm |

|

Low Carbon Steel |

1,100 sfpm |

|

Medium Carbon Steel |

1,000 sfpm |

|

Stainless 300 Series |

800 sfpm |

|

Cast Iron |

1,200 sfpm |

|

Titanium |

220 sfpm |

|

Inconel |

180 sfpm |

|

Copper |

1,200 sfpm |

Pressure isn’t Everything

Efficient machining using high-pressure coolant requires more than the ability to deliver 1,000 psi or more. Flow rate and the size of the opening through which the coolant passes are other critical factors.

The relationship between these three factors is best explained by a fluid dynamics principle named for Swiss mathematician Daniel Bernoulli, which states that an increase in the speed of a fluid produces a decrease in the fluid’s energy. In the case of machine tool coolant, this means that the larger the coolant delivery nozzle, the higher the flow rate must be to achieve the desired pressure at the cutting area. Conversely, the smaller the orifice, the lower the pressure needs to be to achieve the same pressure.

Therefore, for effective high-pressure coolant delivery, the delivery system must be capable of providing enough fluid volume as well as pressure. For milling and turning, the volume requirement is 0.5 gallon per minute (gpm) per machine tool horsepower. Therefore, a 20-hp machine requires 10 gpm (20 hp × 0.5 gpm = 10 gpm), a 30-hp machine requires 15 gpm and a 40-hp machine needs 20-gpm coolant volume.

In drilling applications, the diameter of the tool determines volume. Each inch of tool diameter requires 10 gpm. Thus, a 1-inch drill requires 10 gpm, a ½-inch drill needs 5 gpm and a ¼-inch drill needs 2.5 gpm.

The cutting fluid itself also plays a role in the effectiveness of high-pressure machining. The coolant must have high lubricity to adequately reduce friction; must not be prone to foaming; and have a coolant concentration of at least 8% and no more than 12%.

High Pressure Versus Standard Coolant

The following example illustrates the dramatic difference high-pressure coolant delivery makes when performing the same operation, using the same material, tools and machines. The savings in both production time and tool costs enable a fast return on investment for high-pressure coolant systems.

|

17-4PH Stainless Steel |

||

|

OEM Coolant System |

High-Pressure Coolant System |

|

|

Operation |

Drilling 6x diameter depth |

Drilling 6x diameter depth |

|

psi |

300 |

1,000 |

|

Tool |

0.098 Diameter HSS drill |

0.098 Mitsubishi Micro MZS drill |

|

Holes |

600 |

600+ |

|

Tool life |

Inconsistent Tool life (20 drills used) |

1 drill used |

|

rpm |

2,400 |

10,000 |

|

ipm |

20 |

|

|

fpr |

0.002 |

0.002 |

|

Peck cycles |

||

|

Spot drill |

||

|

End Result |

600 holes (0.600" deep) |

600 holes (0.600" deep) |

|

Drills used |

20 |

|

|

Cycle Time |

8 hours, 24 minutes |

28 minutes |

High-pressure coolant systems provide an opportunity for manufacturers to improve productivity and measurably reduce cost per part. However, it is critical that a high-pressure system is properly matched to applications so it can deliver the precise flow, pressure and temperature control required.

LNS Chipblaster High Pressure Coolant Systems | 814-724-6278 | chipblaster.com

Related Content

CNC Turning Tips for HRSA Materials

Rough-turning, heat-resistant superalloys can be challenging. However, new carbide insert technology provides the capability to perform high-speed, high-feed roughing in a single pass.

Read MoreRepeatability and Rigidity Are Key for Quick-Change Swiss Tooling

A rotary wedge clamping system is said to enable this two-piece, modular tooling system for Swiss-types to offer the performance of a solid tool.

Read MoreThe Ins and Outs of Inserts

Understanding how inserts are made provides valuable insight into how their performance can be optimized.

Read MoreMicromachining Fundamentals

A number of elements must come together to establish an effective process for machining at a micro level. Here we consider four.

Read MoreRead Next

Technologies for Chip and Coolant Management

To the casual observer, removing the chips created during a metalworking manufacturing process may seem about as complicated as emptying a waste basket.

Read MoreEfficient Operation With High-Pressure Coolant

Manufacturers spend millions of dollars on liquid coolants each year to help machine tools cut metal more efficiently. In many cases, however, the effect of this coolant could be greatly enhanced—in some applications by 100 percent or more—by using a high-pressure coolant delivery system.

Read MoreHitting the Coolant Sweet Spot

Toolholders with integrated cutting fluid delivery channels offer threaded, fixed-position nozzles that direct parallel streams of coolant to pre-defined positions at the top of the cutting tool.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)