Keeping Energy Costs Down

This white paper provides information on energy-efficient technologies.

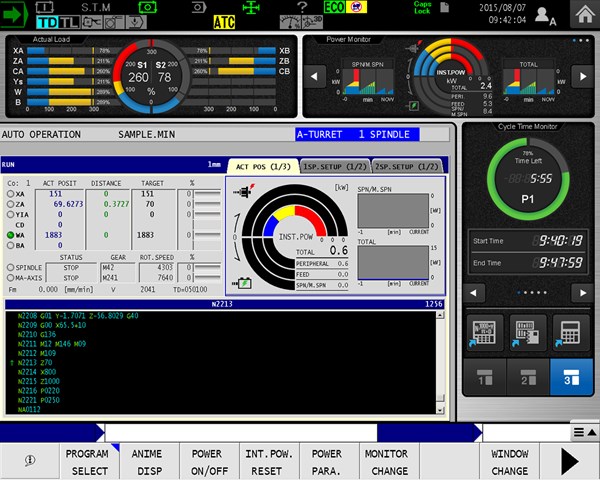

Okuma has prepared a white paper on its ECO suite of energy-efficient technologies for machine tool operation.

Rising energy costs continue to plague machine shops of all sizes by affecting profits. Hidden costs of energy usage in CNC machining such as machine tool idling, unnecessary pump rotation and continuous running of peripheral equipment are some ways energy can be guzzled in the shop.

A new white paper from Okuma America, titled, “Energy-Efficient Machine Tool Technologies for Any Size Shop” explains findings from a 2015 survey of metalworking companies. It revealed that shops could see an energy cost increase of $21,541 in only one year. The white paper describes the ECO suite of energy-efficient machine tool technologies available for the company’s OSP-P300 control. Although targeted at Okuma customers, there are ideas presented that are useful to the industry at large.

The download is available free of charge here.

.jpg;maxWidth=300;quality=90)