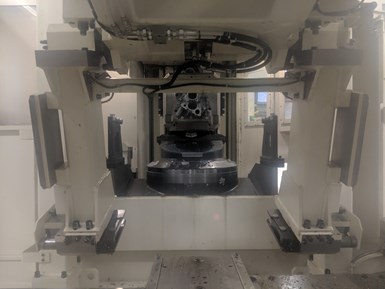

Custom Machine purchased this Yasda 7Ti five-axis horizontal machining center with two pallets from Methods Machine Tools, Inc. to produce a lubrication scavenge pump. The machine’s precision and big work envelope are important features for producing the large, complex part.

One of the most valuable assets to a machine shop is time. “That’s where your profits are, that’s where your customer satisfaction numbers come from, that’s where everything comes from,” says Carl Pasciuto, president and sales team leader for Custom Machine, (Woburn, Massachusetts). But time’s value comes from the fact that it’s limited. “You can’t really buy time,” Mr. Pasciuto notes. “You have to create it.”

Custom Machine had one job in particular for which it needed to expedite operations. With the help of a new Yasda machining center from Methods Machine Tools Inc., the company has built a highly reliable process with fewer setups and partially automated inspection that frees up employees for higher skilled work. The extra time created by this setup has enabled the company to triple throughput, and it hopes to use this momentum to further increase production.

Time for a Change

Custom Machine is a job shop founded in 1969 by Mr. Pasciuto’s father. The company currently has 50,000 feet of manufacturing space and 72 employees running two shifts. It provides high-precision, low-volume complex parts for a range of end markets, including medical, aerospace and defense. “About 50% of what we do flies, either military or commercial,” Mr. Pasciuto says. “So we do have a pretty strong foothold in the aerospace market.”

Reducing the number of setups has saved time and also reduced the opportunity for errors, which is important when working with expensive castings.

“One of our core competencies here is moving fluid, whether it’s fuel, lubrication, or hydraulic,” Mr. Pasciuto adds. One example of this is a pump for a lubrication scavenge system for a new engine in a large commercial jet. More efficient jet engines like this are in high demand, but they take a long time to develop and test. This means that by the time they are approved, production may be already behind schedule. “It falls into our lap to make up for any setbacks they’ve had along the way,” he says. Current demand for this part is 60 pieces per month.

On top of the high demand, the part’s other features make it challenging to produce, including its size. According to Mr. Pasciuto, the part, which is slightly larger than a microwave, is on the large side for this application. Its size, combined with the limited travels and work envelopes of the company’s machines, meant it had required five setups on two separate five-axis machines, along with two manual operations. Each setup took time and introduced more opportunities for errors. “It created more inspection time, it created more rework, and it created a bottleneck for the throughput of the number of parts we had to produce per week,” Mr. Pasciuto says.

The machine is highly accurate, taking into account factors such as thermal expansion, backlash and lead screws. This improves repeatability, so the shop’s machinists don’t have to spend time fixing errors and making tweaks.

The fact that the application involves a casting introduced additional challenges, such as fixturing. “You have to position the casting in a manner in which you can hit the most features,” explains Mr. Pasciuto. “That leads to complex holding devices that position the casting itself.” Foundry items also vary in size and shape, requiring shops to hold positional tolerances. “Being able to actually repeat the machining processes accurately time and time again is paramount in casting manufacturing,” he adds. Additionally, castings can be expensive—the typical casting for this project is in the range of $6,000. This means that it’s essential to not make mistakes that ruin castings. “That comes directly off our top line, so we try to mitigate risk at all costs,” he says.

The Yasda also has on-machine probing, which has replaced some of the inspections performed on this CMM. With more than 800 machined features, the part takes time to inspect, and automating some of this has saved time.

Because the part is for an aerospace application, it also requires tight tolerances. “You have critical bores that fit all the gearing and everything else that run just under five tenths to a thousandth over 19 inches,” Mr. Pasciuto says. “That’s pretty intense, when it comes to holding that on a foundry item.” Tight tolerances require thorough inspection, which is compounded by the fact that the part has more than 800 machined features. “It’s a pretty intense part to inspect with that many features,” he adds. The shop needed two employees to perform all inspections of the part on CMMs and enter the data manually into an SPC program. “That was hours of work,” he says.

Making Up for Lost Time

The Yasda that Custom Machine first purchased has two pallets, which Mr. Pasciuto says are easy to load and unload.

It was apparent that the shop needed a way to streamline production of this part in order to meet demand. Changes to tooling and other factors did not result in the necessary improvements, and it was clear the shop needed a new machine tool. After researching several options, it purchased a Yasda 7Ti five-axis horizontal machining center with two pallets from Methods Machine Tools. The machine stood out to the company for a number of reasons.

One of the most significant features is the machine’s large work envelope. With X-, Y- and Z-travels of 49.2 inches, 39.4 inches and 43.3 inches (1,250 mm, 1,000 mm and 1,100 mm) respectively, along with a vertical rotation of 360 degrees and a horizontal rotation of ± 110 degrees, the machine can handle the large lubrication scavenge pump. “That was one of the deciding factors,” Mr. Pasciuto says. “Yasda’s platform was so flexible that we were able to go from seven setups on our previous equipment down to two.” All machined features are being produced in these two setups, saving a significant amount of time and reducing the risk of errors. “The fewer times you touch something, the more productive you are,” he says.

The work envelope has also enabled the shop to simplify the fixturing for the part. “When you go to a five-axis platform with an open envelope such as the Yasda, you can simplify that by actually extending it, or lollipopping it, we call it,” he explains. “Just put it on one stem and then you can work around and hit five sides of the cube.” Simpler fixtures also help reduce the chances of potentially expensive mistakes, such as loading the part incorrectly or fixtures coming loose.

According to Mr. Pasciuto, another reason the company chose the Yasda machine was its accuracy. He was able to visit the factory in Japan and see the detail that goes into the machines. Everything is hand-scraped, and the platform is very rigid to effectively reduce vibration. “The spindle is very accurate,” he adds, “and they have redundant checks on everything on their machine tools, from feedback mechanisms to backlash and everything else that eliminate all the risks.” These details enable the machines to produce the highly accurate parts this application requires.

Accuracy saves the shop time. The machine takes into account factors such as thermal expansion, backlash and lead screws, making it repeatable so machinists don’t have to spend time fixing errors and making tweaks. According to Mr. Pasciuto, time spent correcting problems is time wasted chasing the machine. “Every time you’re chasing something, it’s time you’re losing,” he says. “You’ll never get it back.”

Additionally, the machine’s accuracy has enabled the shop to shift experienced employees to higher skilled work. “The other thing you can depend on when you have accurate machines is you don’t need your highest skilled people,” Mr. Pasciuto says. As with many other shops, Custom Machine is looking for new machinists. Until shops are fully staffed, it’s important for employees to work as efficiently as possible using their full capabilities. If a job has a reliable machine tool, a reliable process and a solid setup, a lower-skilled employee can run it while higher-skilled employees can focus on new jobs and process improvements.

The new machine has helped improve the inspection of the pump as well. The Yasda has on-machine probing, a feature the shop’s previous machines did not have. This has enabled the shop to automate some of the part inspection, and with more than 800 features on each part, this adds up to significant time savings. “It’s still an hour, but it’s much less human interaction,” Mr. Pasciuto notes. “There are some features that still need to be checked manually, but for the most part we’re automating anything we can.” And because of the on-machine probing, Custom Machine has reduced the number of employees inspecting these parts from two to one, shifting another employee to higher-skilled work.

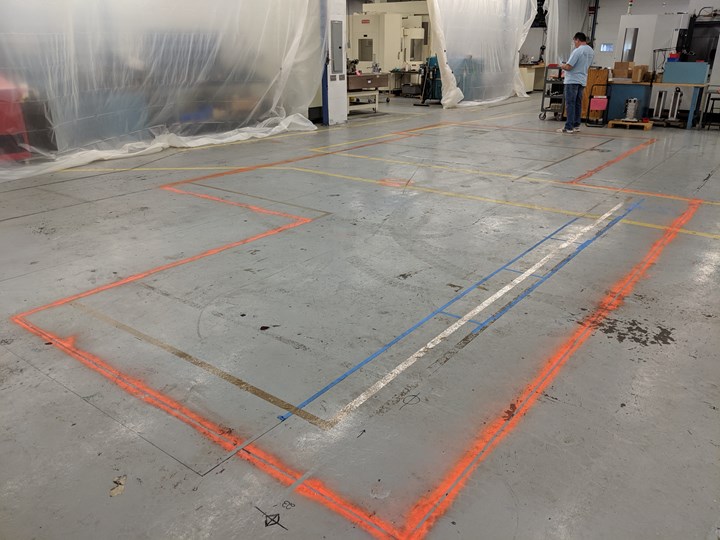

The two-pallet Yasda has enabled Custom Machine to triple throughout, but the company still cannot meet the demand of 60 pieces per month. The shop has purchased a second Yasda, this one with six pallets, that it expects to again triple throughput and exceed demand.

The Yasda has enabled Custom Machine to dramatically increase its throughput of the part. “If you back figure what time it took before to where we are now, a triple throughput is probably conservative,” Mr. Pasciuto says. However, even with this progress, the company still can’t meet the demand of 60 parts per month. So, it has purchased a second Yasda 7Ti, this one with six pallets. These additional pallets, along with the improvements made on the first Yasda, will enable the company to run parts lights out through the weekend. Mr. Pasciuto estimates that the new machine will again enable the company to triple output and exceed 60 parts per month.

Methods Machine Tools Inc. | 1-877-668-4262 | methodsmachine.com

Custom Machine LLC | 781-935-4940 | customgroupusa.com

Read Next

A Different Kind of Machining Center

If one horizontal machining center is good, then three on a single platform should be better, right? That’s the thinking behind the Multicenter concept from Italian builder, Porta Solutions. It blends the volume production capabilities of rotary transfer technology with the flexibility of a machining center in a single platform.

Read MoreThe Shift to Horizontal Machining Centers Gathers Steam

Metalworking companies, especially job shops, continue to invest more heavily in HMCs. This trend points to the inherent capability and flexibility of these machines for producing complex, high-value workpieces.

Read MoreFour Questions a Shop Considering HMCs Should Ask

Compared to vertical machining centers, horizontal machining centers offer the potential for improved spindle uptime, cycle times and throughput. Although they come with a higher price tag, their higher productivity can be significant to shops of all sizes, as Valley Tool has experienced.

Read More

.jpg;maxWidth=300;quality=90)