The Multitasking Knowledge Center at imts.com/spark covers innovations across a range of multipurpose machining center platforms, including Swiss-type lathes.

Various Gardner Business Media brands, including Production Machining magazine, are helping AMT — The Association for Manufacturing Technology provide informative and helpful content to its International Manufacturing Technology Show (IMTS) spark digital experience. One aspect of this is the various Knowledge Centers on the IMTS spark site (imts.com/spark), which take deep dives into specific manufacturing technology and processes by way of articles, graphics and video.

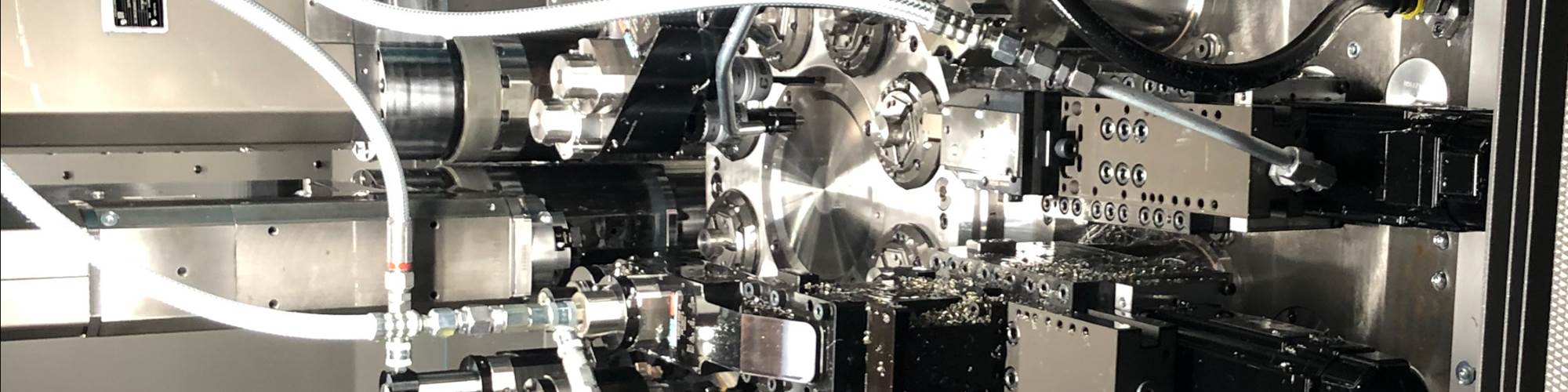

I developed the Multitasking Knowledge Center, which highlights trends related to Swiss-type lathes, turn-mills, high-production machining equipment (rotary transfer machines, single- and multi-spindles and so on) and additive manufacturing integrated into CNC machining center platforms. In fact, the article related to metal additive manufacturing capability as it is being added to machine tools gives you an idea as to what the subcategories within each of those Knowledge Centers look like.

Here are a few other Knowledge Centers you might find interesting:

-

Trends in Parts Cleaning. Production Machining Senior Editor Lori Beckman, who recently became a board member of the newly formed Manufacturing Cleaning Association, compiled the content for this Knowledge Center. As the geometry of machined and 3D-printed parts continues to become more complex, new technology must be developed to effectively clean those parts. Examples described in this Knowledge Center include ultrasonics, cyclic nucleation and vector kinematics. Latest cleaning regulations, which are ever changing and often very stringent, are also covered.

-

Practical Approaches to Automation. Machine-tending robots are becoming easier to program and integrate. Collaborative robots, those that can operate safely in the same area as humans, are a good example of this. That said, there are multiple other considerations for establishing a safe and reliable process to enable long stretches of unattended machining either during the day or overnight. Sometimes it’s best to start small. Plus, shops must be mindful of how best to communicate the “whys” of integrating robots and other automated processes to their workforce. It’s not about replacing jobs.

-

Five-Axis Machining. Demonstrations of five-axis machining at trade shows or online with video often show choreographed dance moves between a cutting tool and workpiece for components such as turbine impellers that require full five-axis motion. The majority of five-axis machines are not used for true five-axis contouring moves like this, though. Instead, simply being able to access five faces of a more prismatic part can greatly eliminate the number of setups required to complete it. Still, an effective “3 + 2” process such as that requires thought about which workholding strategy, programming technology and cutting tool geometry are optimal.

-

Digital Manufacturing. Machine shops are leveraging software and machine monitoring now more so than ever. However, looking at “digital manufacturing” from a 30,000-foot level can be overwhelming and ultimately unhelpful when the goal is to improve efficiencies through digitalization where the rubber meets the road on the shop floor. This Knowledge Center describes concrete ways shops can use data to enable more effective cutting tool management, preventive maintenance, data-driven manufacturing and overall equipment effectiveness (OEE) tracking.

-

Additive Manufacturing for Production. This is a technology that remains murky among some in the CNC machining community with whom I’ve interacted in which machining is their core business. Many are familiarizing themselves with the process of building metal or polymer parts layer by layer. Some are buying inexpensive polymer 3D printers to produce prototype parts, jigs or fixtures to use in the shop. But, what about AM for part production? Has this technology reached the point whereby it no longer simply offers the “promise” of being a viable, alternate production method compared to (or combined with) CNC machining, especially for metal parts? This Knowledge Center makes that case, although the definition of “high volume” for shops dropping brass valves off of multi-spindles at a rate of a few seconds at a time differs from “high volume” in the metal additive manufacturing world.Photo Credit: Mazak Corp.

In addition to Knowledge Centers covering specific equipment and technology, there are others that cover topics such as sister publication Modern Machine Shop’s latest Top Shops benchmarking survey findings as well as automotive industry trends.

Related Content

Five-Axis Machining Center Performs Cutting Operations in a Single Setup

PMTS 2023: Haas’ UMC-350HD is a compact five-axis universal machining center Capable of performing 3+2 and five-axis machining simultaneously.

Read MoreCompact VMC Built for Diverse, Simultaneous Applications

The compact model is well suited for shops that want an integrated 5-axis solution for virtually any part that has previously required multiple operations or setups.

Read MoreMazak Custom Machining Solutions Feature Automation, Digitalization

IMTS 2024: Mazak features advanced machining solutions designed to boost productivity in automation, multitasking capabilities and machine tool technology.

Read MoreFive-Axis Machining for Small Prismatic Parts

New to the U.S. market, this compact machine could enable precision turning shops to win complex, more prismatic work in medical and other industries.

Read MoreRead Next

Turn-Mills: Being About the B-Axis

With the addition of powerful B-axis milling spindles and automatic toolchangers, turn-mills combine the best of milling and turning worlds.

Read MoreSwiss-Types Offer Advantages Beyond Watchmaking

CNC sliding headstock lathes are becoming more popular among traditional machine shops for their multitasking capabilities, some offering B-axis milling spindles.

Read MoreMultitasking Machining Equipment: Now the New Normal

Equipment that can turn, mill and more is quickly becoming the standard in metalworking technology. These machines can produce increasingly complex parts in a single setup yet are easier operate than ever before.

Read More

.jpg;maxWidth=300;quality=90)