Measuring the Merit of Ceramic Cutters

In testing new ceramic microtools, a precision dynamometer ensures that cutting forces are measured precisely so tool performance parameters can be determined.

Tusa Precision Tools SA (Ticino, Switzerland) recently has begun to explore the possibility of manufacturing ceramic cutting tools because of that material’s hardness and reliability. These are critical characteristics for Tusa’s cutting tools that are used to make precision components such as those used in watches. Before a machine shop can confidently use ceramic cutters, though, much testing must be done. While partnering with a local university to begin its research, Tusa and its team discovered that a dynamometer has been an invaluable component for testing the cutting tools.

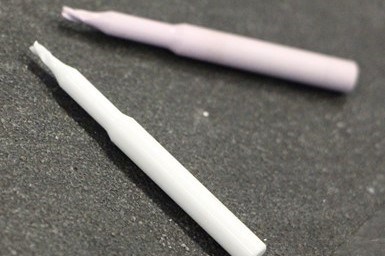

Each ceramic material produces different process characteristics when cutting. Photo courtesy of Kistler Group

“Production of highly intricate components for watch movements must meet the highest requirements. The tolerances are sometimes in the micrometer range,” says Gennaro Teta of Omnino Technology, Tusa’s development partner. Mr. Teta’s attention was drawn to the potential of industrial ceramics in his quest for new ways to improve tool life and process reliability for his customers.

Watch manufacture is one of the many sectors where the trend is moving toward highly automated, unmanned production. “What’s the point in being 10% faster if you can manufacture throughout the night at a slightly slower speed knowing that the process is reliable?” Mr. Teta asks. Ceramic material is harder than steel, so it can offer significantly greater wear resistance as long as the cutting forces are kept under control.

Tools Can Last up to 30x Longer

Mr. Teta points out that the new ceramic can extend tool life by up to 30x while maintaining precision comparable to more traditional cutting tool materials. Tusa approached the Polytechnic University of Milan in nearby Italy to assist with the development of these ceramics.

Mr. Teta notes that while industrial tests show that while ceramic tools can offer greatly improved tool life , there are enormous variations depending on the substrate. “This gave us the idea of collaborating with the university to develop different ceramic mixes and to carry out tests on them,” he says.

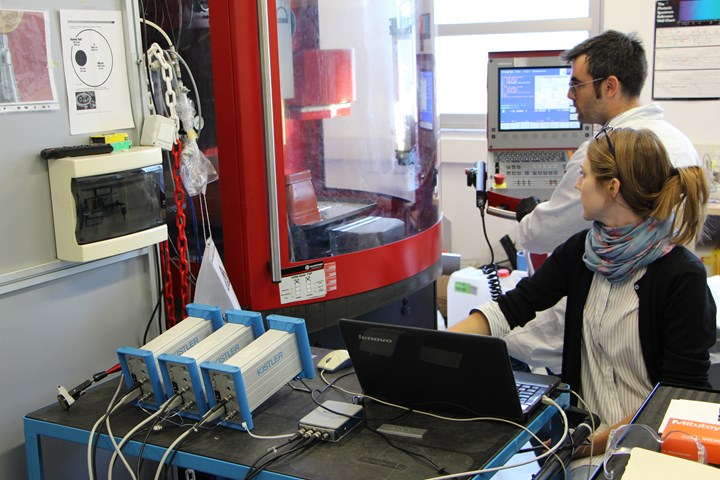

At the university’s school of mechanical engineering, Giulia Giovannelli and Paolo Parenti are in charge of researching new materials and cutting tools. For their work, they are able to make use of electron microscopes, precision machining centers and special machines for tribological studies.

At Milan’s Polytechnic University, Giulia Giovannelli and her colleague, Paolo Parenti, are investigating ceramic cutting tools with the help of a measurement solution from Kistler. Photo courtesy of Kistler Group.

The two also use a MicroDyn dynamometer from Kistler, which is said to be one of the smallest dynamometers available. Because of its high natural frequency, the device supplies values for force and torque on all three axes, even at high speeds. The results of all three axes are then determined with the help of an algorithm. The lower this value is, the longer the tool life will be, according to Ms. Giovannelli.

Measuring only 30x30 mm, MicroDyn has a high natural frequency of 15 kHz on all three axes and enables precise measurement of dynamic forces up to 500 N and torques up to 50 Nm. Measurements are taken directly on the individual cutting edges at speeds up to 120,000 rpm. The piezoelectric crystal rings used for the measurement is said to ensure high sensitivity and a low response threshold.

Because of Kistler’s MicroDyn the cutting forces on the tool can be measured precisely at speeds up to 120,000 rpm. Photo courtesy of Kistler Group.

The rings are installed in such a way that temperature influences are compensated. The measuring chain is completed by the laboratory charge amplifier to provide efficient signal conversion and data acquisition.

Crystal Clear Test Results

“In the test setup for Tusa, a micro-cutting tool is used to mill a brass plate. We’re testing three different ceramic materials with two different sets of cutting parameters,” Ms. Giovannelli explains. The research done at Polytechnic University revealed that one of the three materials regularly displayed better characteristics for the cutting forces generated. For cutting depths of 1.3 mm as well as 0.5 mm, the force for one ceramic material was significantly lower than the other two. The material generating the lowest force also achieved the best surface quality.

For Ms. Giovannelli, however, this is merely the beginning. “In the initial phase, we’re only looking at shoulder milling,” she says. “The picture could look entirely different for slot milling, which is used to apply the main pattern to the brass plate.”

Still, Mr. Teta is enthusiastic about the result. "This shows that we’re on the right track and that we have suitable material,” he explains. “The next step is to test the material in a realistic industrial environment on another machine. Then we will see whether the values determined in the laboratory can be reproduced with similar cutting parameters. There’s a long way to go before the material can be used in industrial production, but the first step has already been completed successfully.”

Read this article for further information about ceramic cutting tools:

Related Content

Parting Off: The Case for Standardizing on Sawing

The value of rotary saw cutting for parting off operations could boil down to simple economics paired with process efficiency gains.

Read MoreWhat Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

Read MoreCNC Turning Tips for HRSA Materials

Rough-turning, heat-resistant superalloys can be challenging. However, new carbide insert technology provides the capability to perform high-speed, high-feed roughing in a single pass.

Read MoreBroaching Tool Technology For Lathes Used to Slot Inconel Parts

This shop finds value in using an indexable-insert-style broaching tool to create blind-hole slots in heat-treated Inconel aerospace parts on a CNC lathe.

Read MoreRead Next

The Ins and Outs of Inserts

Understanding how inserts are made provides valuable insight into how their performance can be optimized.

Read MoreTurning Exotic Materials

Heat-resistant superalloys and titanium alloys are difficult to machine. This overview looks at machining demands and some recent developments that have elevated performance and process security in turning these materials.

Read MoreGetting the Most Out of Hard Turning

Traditionally, production of most parts made from hard or hardened materials, defined as those at or more than 45 HRc, required dedicated grinding equipment and processes.

Read More

.jpg;maxWidth=300;quality=90)