Milling Hard-to-Machine Materials on a Micro Scale

The idea of a tool that effectively controls heat with a special grade of carbide, a new coating and internal channels that deliver cooling through ports in the shank where the milling flutes begin, is worth a look.

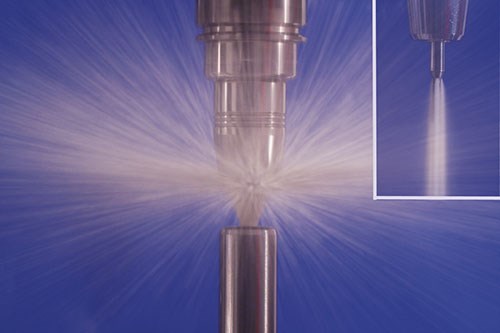

The multiple streams of pressurized coolant at the cutting edges. This method of coolant delivery also flushes chips out of the cutting zone.

Controlling heat at the tool/workpiece interface is an operator’s main concern. Therefore, the idea of a tool that effectively controls heat with a special grade of carbide, a new coating and internal channels that deliver cooling through ports in the shank where the milling flutes begin, is worth a look.

Recently, PM’s sister publication, Modern Machine Shop, published an article titled “Managing the Micro-Milling Process with Tiny Cutters,” in which the author, Mark Albert, explains the CrazyMill Cool solid carbide milling cutters from Mikron Tool.

According to the article, these cutters are capable of significantly higher cutting speeds and depths of cut in tough-to-machine materials compared with conventional end mill designs in this size range. These results are obtainable in stainless steel, titanium, chrome-cobalt alloys and other so-called super alloys. Read more here.

Related Content

-

Tool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

-

The Value of Tool Monitoring on Rotary Transfer Machines

By using a tool monitoring system, shops can save costs associated with machine maintenance and downtime for tool changes while increasing cutting performance.

-

Parting Off: The Case for Standardizing on Sawing

The value of rotary saw cutting for parting off operations could boil down to simple economics paired with process efficiency gains.

.jpg;maxWidth=300;quality=90)