OSHA Needs to Enforce its Tower Regulations

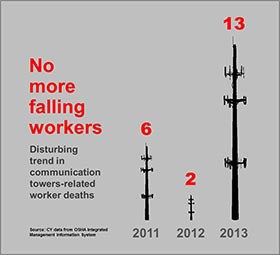

Four communications tower related deaths have already occurred this year, according to OSHA, and more were killed last year than in the prior 2 years combined. Every one of them was preventable.

OSHA Regulation 1910.1053 (a)(19) could have saved these lives.

Employee safety is a responsibility of all of us—employers, employees and even the regulators. We are puzzled as to why OSHA fails to enforce its existing rules on fixed ladders to protect the safety of communication tower workers and wind generator workers.

Four communications tower related deaths have already occurred this year, according to OSHA, and more were killed last year than in the prior 2 years combined. “Every one of them was preventable”- from OSHA March 4 Quick Takes.

“We are very concerned about this sharp rise,” says Assistant Secretary of Labor for Occupational Safety and Health Dr. David Michaels, in a Feb. 25 message delivered to the National Association of Tower Erectors. “The fatality rate in this industry is extraordinarily high—tower workers are perhaps 25 times more likely to die on the job than the average American worker.”

In my problem-solving practice, I ask three questions to get our remediation steps off in the right direction.

Let’s see how this can be used to frame the 21 needless tower deaths in the U.S from 2011-2013.

Is there a process? In the OSHA case at hand, this might better be framed as, “Is there a regulation that addresses this?”

Is there a regulation? Yes! OSHA has a fixed ladder regulation on the books: 1926.1053(a)(19). Where the total length of a climb equals or exceeds 24 feet (7.3 m), fixed ladders shall be equipped with one of the following:

- 1926.1053(a)(19)(i): ladder safety devices or

- 1926.1053(a)(19)(ii): self-retracting lifelines and rest platforms at intervals not to exceed 150 feet (45.7 m) or

- 1926.1053(a)(19)(iii): a cage or well and multiple ladder sections—each ladder section not to exceed 50 feet (15.2 m) in length. Ladder sections shall be offset from adjacent sections, and landing platforms shall be provided at maximum intervals of 50 feet (15.2 m).

Is the regulation being followed? Great question. How many of the tower deaths involved workers working on ladders that were in compliance with 1926.1053(a)(19) (i) (ii)(iii)?

Is this regulation effective? Not if it isn’t being enforced. Safety of the people and processes under our authority is our greatest responsibility.

- Why aren’t the fixed ladders on communications towers and wind generators held to the same fixed ladder safety requirements as those in general industry?

- Why doesn’t OSHA use the existing rules on the books to stop the death toll in this industry?

This doesn’t require new technology, just enforcement of the existing proven effective regulation already on the books.

When I testified at OSHA in February, I was asked, “Why does industry always come in against rules? Why doesn’t industry come in and say they are for rules?”

I think all of us are for OSHA using its existing enforcement authority to ensure that everyone abides by the demonstrated effective ladder safety requirements of 1926.1053 (a)(19)(i-iii).

I am certain that there are 21 families out there who would ask why their loved one wasn’t entitled to the same fixed ladder protections as everyone else in general industry seems to be. Why doesn’t OSHA enforce 1926.1053(a) (19) (i-iii)?

Originally posted on PMPAspeakingofprecision.com blog.

Read Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.jpg;maxWidth=300;quality=90)