Outsourcing Optimizes Control Panel Construction

Given the multiple challenges associated with in-house panel building such as quality design, expertise, support and technology, outsourcing quickly becoming a viable option.

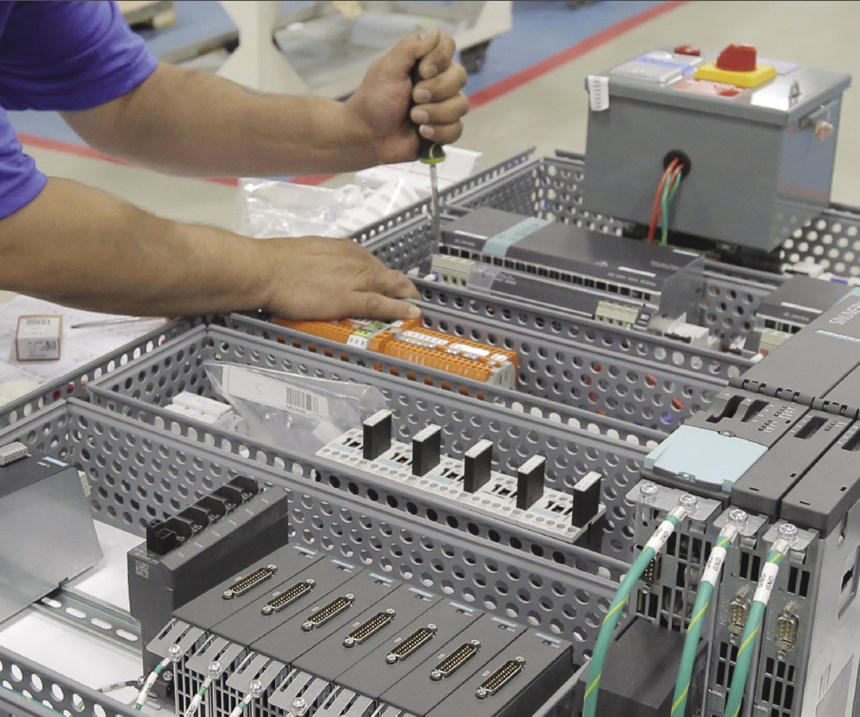

Panel building on machine tools is no longer as simple as wiring a few components. Now, there are more deadlines, cost pressures, standards, new directives and increasing pressure to innovate. Besides common problems related to time, cost, compliance and quality, there is also an increased degree of automation in the pre-fabrication of cables and production of sheet metal parts. In addition to the mechanical design and development of the automation concept, planning the electrical power supply and distribution is the third engineering discipline involved in producing a new machine. Electrical planning provides the framework for the automation engineer, as it involves specifying basics such as communication, topology and the control concept.

Increasingly, the daily work of electrical designers involves more than planning. It includes downloading, storing, processing and backing up data. Data management is an important part of the process, but it is time-consuming. To save time, machine tool companies should create and implement a plan for handling data. Machine tool builders with more than one electrical designer should relocate product databases to a central server. Data only needs to be imported once, then every user can access it. Because the engineering process is closely tied to other processes like procurement, storage, project-specific provisioning, assembly and inspection, it is useful to connect them electronically. Electrical computer-aided design (ECAD) programs can connect to enterprise resource planning systems, making it easier to calculate the price of a control panel. The prices can then be transferred from the ERP system to the ECAD solution’s product database.

Even though clients expect high-quality manufactured products, companies need to keep costs low to remain competitive. Machine tool builders typically think of cabinet costs originating from engineering, devices and materials, assembly and wiring. Engineering costs typically comprise 45 percent of the overall cost, devices and materials make up another 45 percent, and assembly and wiring are the remaining 10 percent. However, there are also hidden costs including ordering and storing material, time from procurement, time spent by engineering to coordinate with suppliers and redesign the cabinet, and payment terms dictated when ordering material.

Increasing costs stem from various sources. Documentation is becoming more complex because end users and machine builders need more detail for better, more independent production. The communication between integrated components is also increasing. A basic controller now has measuring and monitoring devices for keeping track of energy usage and machine condition, making planning more complex and time consuming. In addition, demands on service personnel have increased, as they must have the information to quickly and efficiently replace components.

Purchasers may want a good price, but that does not necessarily mean that the control panel is economical. The burden of electrical planning for a component is often overlooked. Manually creating a complete dataset for a new project in an ECAD program often takes more than 2 hours, so the ability to use existing data is important. Fortunately, ECAD systems often offer complete data packages that can be downloaded via data portals.

The use of tools for daily work is also changing. Until recently, “drawings” were used to create electrical plans. ECAD programs offered functions for easily and precisely placing and interconnecting circuit diagrams. Then, the software added object orientation capabilities. A placed symbol is no longer simply a collection of drawn lines, but one of many views of a device that are integrated into the control panel. Users can take advantage of ECAD software’s object orientation and automation functions in their daily work.

This “toolbox” concept has been popularized in various industries such as packaging, printing, converting and metal forming machinery. It allows slightly modified and next gen machine builds without redoing the entire electrical landscape, saving money for builders and integrators.

Like many in-house projects, building control panels in house can lead to delayed deadlines and wasted money and effort. Some companies cannot afford to build panels in house, and others build cabinets in house to keep their workforce employed. However, in today’s competitive business environment, builders must evaluate whether reallocating resources could reduce costs. Outsourcing to companies that specialize in electrical control and cabinet builds can establish milestones with contract manufacturers for timeline-based pricing, thus eliminating project management uncertainties and reducing time-to-market for the builder, in addition to saving time and material costs.

Innovative projects and complex automation integrations often rely on multiple concepts to stand out in the market. But companies may not have enough resources to have staff developing new projects. By outsourcing panel and cabinet builds to another company, machine tool builders can use technologically advanced engineers to develop new projects while eliminating excess labor and engineering costs.

As software, automation technologies and tools continue to evolve, companies are placed in a competitively disadvantageous position. These tools and programs can require a license or expensive user fee. By outsourcing, machine builders can have access to the newest and most appropriate technologies for projects in a cost-effective manner. Problems with equipment or the software can also lead to inactivity and unplanned expenses. Outsourced support staff can monitor equipment efficiencies, diagnose problems and repairs equipment more effectively and economically.

Partnering with another company, like Siemens, to build panels can streamline and simplify the process. Outsourcing can help machine tool builders on the path to digitalization and provide them with support through the stages of panel building, including design, quoting, order, build and support. Siemens accomplishes this with the help of a “Solution Partner,” an authorized electrical distributor and job shop located in close proximity to the machine tool builder.

In the design stage, Siemens assists with UL/EC standards and sizing optimization and offers component optimization content-neutral devices. Additionally, the company can evaluate specification requirements and provide support with application of standards and certifications based on the end user’s market, physical location and more.

Once a project’s details are set, there are no complicated purchased order or line items, simplifying the ordering process. This is one of the key reasons for outsourcing cabinet builds. For a typical package, the bill of material may have more than 200 line items, each of which must be entered and tracked by someone in procurement. Outsourcing allows that procurement person to focus on obtaining better pricing instead of administrative work. In addition, there is no need to store pieces and parts for the panels in-house, as the partners maintain that carrying cost.

Siemens builds its panels in a UL-certified production facility, with a dedicated project manager onsite to handle engineering change notices (ECN) and communication. The company and its partners provide quality control and assurance, along with scheduling and resource management. It also performs continuity testing, automatically routes the wiring and provides custom painting per specifications. All control panels feature a one-year warranty, pre- and post-purchase consultations, a communication log and a transparent ECN process.

Outsourcing panel and cabinet production to Siemens has several additional benefits. The company acts as the builder’s single source for all ordering, service, support and delivery, with comprehensive project management. Outsourcing also reduces the total cost of ownership for the machine tool builder, which includes engineering, electrical and manufacturing engineering costs. In addition, the company has invested in a variety of panel shops to develop “best practice” protocols for various machine categories.

Machine builders can leverage Siemens’ global agreements to receive competitive pricing and take advantage of extended payment terms (at the completion of the project instead of when the order is placed). The company’s global network of partners has years of experience designing and building panels, and can optimize overall design, cabinet heating and cooling, footprint, Siemens content, third-party content, and more.

In the year since implementing this control panel initiative, Siemens says several machine tool companies have reported substantial savings.

About the Author

TJ Terrell

TJ Terrell is the business development manager for Siemens Industry's machine tool business.

Related Content

What Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

Read MoreThe Control’s Role in Machining Complex Parts

This company that produces medical implants finds value in the CNC for its turn-mill equipment that helps speed setups and simplify programming when producing intricate parts complete.

Read MoreLone Shop Machinist Benefits From Five-Axis CAM Modules

This California shop owner applies five-axis strategies for more efficient milling of parts with challenging geometries, free-form surfaces and deep cavities.

Read MorePrecision Machining Technology Review: September 2024

Production Machining’s September 2024 technology showcase includes some of the latest technology from Expand Machinery, Paperless Parts, Monaghan Tooling Group, Walter USA and more.

Read MoreRead Next

Seeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)