Quick-Change Starts with the Lock Nut

TOMZ is a Connecticut shop that has begun using a new lock nut wrench and is enjoying its benefits on the shop floor where its operators are wearing significantly fewer bandages on their hands.

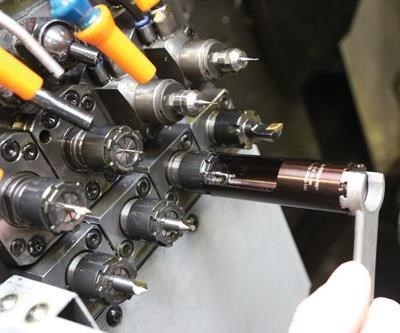

Using the extensions available on the Rego-Fix collet wrench, operators can access cutting tools for change-over from a safe distance.

Changing tools in the close quarters of a Swiss machine tool can be a painful exercise as hands tend to brush up against tool tips that are sharp and close to the tool that the operator is trying to change out. Packed with 15 to 20 cutting tools, the space between each toolholder, especially in gang-type setups, can be as small as 2 inches. Not much room for a hand.

REGO-FIX Tool Corp. has created a simple tool to help shops alleviate the cuts and abrasions that so often come from tool changing on a Swiss machine. We published an article that discusses the advantages of this new lock nut wrench that enables the operator to access the lock nuts on collets without contacting adjacent cutters.

TOMZ is a Connecticut shop that has applied this new tooling system and is enjoying its benefits on the shop floor where its operators are wearing significantly fewer bandages on their hands, while the shop has improved its throughput by virtue of faster change-overs. Click here to read “Locking Nut Improves Tool Change-Outs.”

.jpg;maxWidth=300;quality=90)