Reasons Why Steel is Vacuum Treated

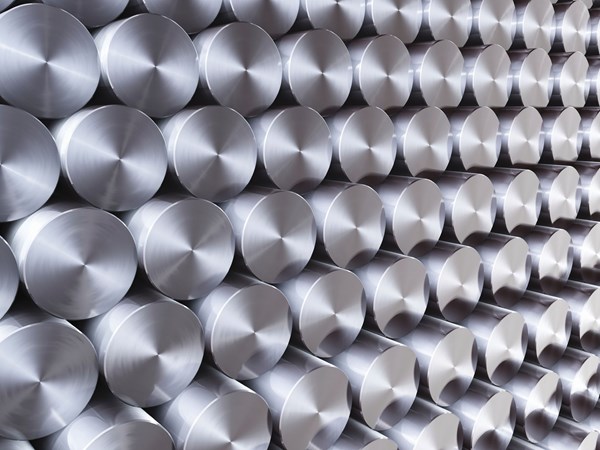

Vacuum treated (vacuum degassed) steel is used for critical applications that require steel with an exceptionally high degree of structural uniformity, internal soundness, and other characteristics that may be impaired by the effects of uncontrolled amounts of dissolved gases.

Vacuum treated (vacuum degassed) steel is used for critical applications that require steel with an exceptionally high degree of structural uniformity, internal soundness, and other characteristics that may be impaired by the effects of uncontrolled amounts of dissolved gases. Vacuum degassing treatments, along with various deoxidation practices, are specified to control the amounts of dissolved gases in the steel. The benefits of vacuum treatment include:

- Reduced hydrogen content, which reduces steel’s tendency to “flake” or become “embrittled.”

- Reduced oxygen content, which makes it easier for the steel to conform to restrictive microcleanliness requirements.

- Improved recovery and uniformity of alloying elements and other additive distribution.

- More controlled steel composition.

- Higher and more uniform transverse ductility, improved fatigue resistance, and improved high temperature performance.

- Can be used to achieve exceptionally low carbon content that are otherwise unobtainable by conventional means.

What are some situations where vacuum treatment is employed?

- Large forgings and large cross sections where hydrogen would otherwise remain and contribute to flaking and embrittlement.

- Bearings where uniformity throughout the section is important for critical performance.

- Inverted delta, human critical safety applications where steel toughness and performance place high demands on the steel’s properties in all directions.

The removal of oxygen by degassing is a challenge for the steelmaker, because this element is extremely reactive: It can exist in the steel in many forms, such as free oxygen; it can dissolve in the melt as a soluble nonmetallic oxide; it can combine with carbon to form gaseous oxides; and it can exist as complex oxides in the accompanying slags and refractories in the process.

Originally posted on PMPAspeakingofprecision.com blog.

Related Content

-

Machining More Than Metal

Plastics for medical and industrial applications present different challenges than metals as I’ve reported on over the years.

-

The Basics of Rotary Broaching

This broaching process creates a non-round shape on the inside or outside of a part with a broach tool.

-

Why Are We Writing About a Shop Making Custom Baseball Bats?

I recently learned about a 153-year-old manufacturer that has produced billions upon billions of precision, metal pins which started another business making one-off wooden baseball bats. (Like I asked it to do for me and you’ll see at this year’s Precision Machining Technology Show). Here I explain why it’s worth the time to read that article.

.jpg;maxWidth=300;quality=90)