Recognize and Challenge Assumptions

How many of us realize that we have a choice between solutions, and that lowest price doesn’t necessarily mean lowest cost to us?

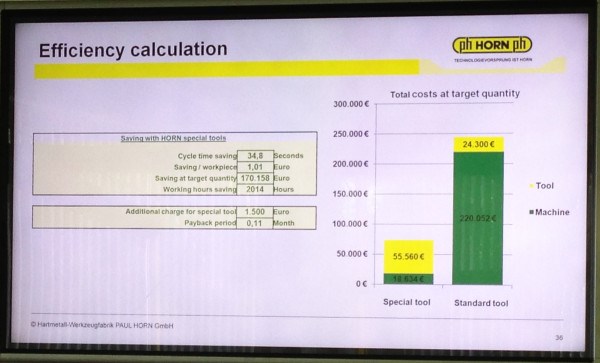

Yes, the tool is more expensive, but it might be worth it.

I remember the first time I sat down to work on quadratic equations and discovered there was more than one possible solution to the equation.

How many of us realize that every day in our businesses, we are solving equations that have more than one solution? How many of us realize that we have a choice between solutions, and that lowest price doesn’t necessarily mean lowest cost to us?

At Horn Technology Days, I attended a session on Customer Specific Tool Solutions presented by Todd Hayes. Todd started his presentation with a challenge to the assumption that ROI is only about dollars.

As Todd put it, “ROI is not just about dollars. Increase my tool life. Increase my machine operating time, increase my accuracy (especially on features tied to another), reduce my time in cut by simultaneous machining. Give me my weekend back. Let me run lights out.”

This rang true with me. When I produced steel for machine shops, the purchasing agent was always looking at lowest price per pound for the steel.

I told him that what he should be looking at is the lowest cost to produce the part. Steel price was just one part of that cost. The cost to machine it was another. Todd was talking about creating special tools to solve problems in production.

For short runs, the cost of a special tool is prohibitive. Even though not all of us are quoting short runs, how many of us are still using short run thinking? How many of us are solving for lowest tool price rather than optimum output? Ask yourself:

- What if the custom tool (or special steel grade) saved me several changes per day on several machines?

- How much more machine operating time will I gain?

- How much utilities will I save by not needing all the CFM of compressed air that we all overuse when we change a tool?

- How much will I save because I have eliminated variability and/or have better control over the chip so I do not have to inspect for chip weld and out of spec surface finishes?

I am not exhorting you to go out and buy specialty tools for every job, just like I was not asking my customers to buy the premium machining grades of steel for every job. But I am asking you to recognize and challenge your assumptions about how you decide to purchase, just as I had to recognize and challenge my assumptions that there was only a single “solution” to those equations I faced in class that day.

Lowest price on purchases or lowest cost of production? Two solutions—you get to choose one.

Originally posted on PMPAspeakingofprecision.com blog.

.jpg;maxWidth=300;quality=90)