Shining Light on New Machining Technology

Equipment and software that can enable precision CNC machine shops to grow and become more efficient continue to be developed.

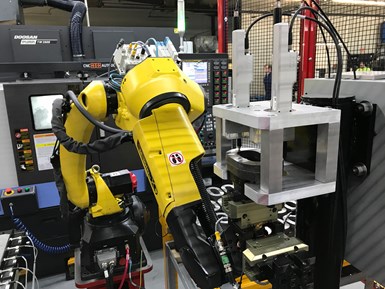

Robots are just one form of automation available to CNC machine shops. Production machine shops continue to eye automation as well as high-volume equipment that offers the flexibility to accommodate smaller batch sizes when necessary.

Every other year in September, the spotlight on new machining equipment, software and concepts seems to shine a bit brighter as many people like you and me find our way to Chicago to attend the International Manufacturing Technology Show (IMTS). But, as you likely know, the ongoing COVID-19 pandemic means there is to be no in-person IMTS for us to experience this month.

Traditionally, Production Machining’s August and September issues in even-numbered years include a number of blurbs describing new technology IMTS exhibitors plan to unveil at the show. Admittedly (and I’m getting into some media “inside baseball” here), prior to this year’s show cancellation, publications like ours were sent only a fraction of the number of new product press releases we’d typically receive from exhibiting companies.

So, there were two paths we could have taken. One was to treat an issue like this as any other, pushing brief introductions to an abundance of advanced, new technology to future issues as we come to learn about them. Or, the other, the one we’re taking with this article, was to personally reach out to various show supporters that serve our precision machining industry to learn about — and present here and online — new technology they have recently developed.

To be clear, the point of this is not to bemoan the fact that the physical IMTS as we’ve come to know and appreciate won’t be going off this year. And it’s not possible to provide overarching, comprehensive coverage of all technology that’s new to the market in that article. Rather, the article includes snippets from conversations with various equipment and software suppliers that shed light about newly developed technology to support current industry trends and, thus, meet the needs of companies like yours striving to grow and become more efficient.

Not to present this information in some way would be a disservice to both you and the technology providers to our niche industry.

What’s interesting is that from all companies mentioned in the article, these two themes emerged: there are various flavors of automation and flexibility is being built into high-production equipment. After reading the article, go to gbm.media/newtech to find links to longer blog posts fleshing out these concepts a bit more with commentary from the suppliers.

Two technology trends: There are various flavors of automation, and flexibility is being built into high-production equipment.

On a bigger scale and for a broader audience, IMTS’ show producer, AMT – The Association for Manufacturing Technology, has developed an alternate digital experience it calls IMTS Spark. This platform — which will consist of webinars, podcasts, self-study curriculum, online chat rooms and lunch-and-learn programs — is designed to connect shop people like you with an alternate means to discover the latest manufacturing advancements, learn from industry experts, take educational deep dives and experience networking opportunities. Besides technology, timely topics such as supply chain solutions, succession planning, workforce development and more will be covered.

IMTS Spark is being produced in conjunction with Gardner Business Media, our magazine’s publisher, and the editors at Production Machining have had a hand in helping to generate quality content for it.

Plus, AMT’s live IMTS Network runs September 14-18, which the association says is designed to offer unique manufacturing insights, stories and developing news. It will include:

- IMTS Today. Live broadcasts from the U.S. manufacturing community.

- Outside the Shop. A casual video series that explores manufacturing technology utilized in unconventional ways.

- Profiles in Manufacturing. In-depth features that tell emotional narratives and highlight the many faces that comprise the manufacturing industry.

- Tech Peek. Fun and whimsical short-form videos that feature emerging technology that will be impactful to our industry.

AMT also wants to hear your story to share with others. Specifically, something you’ve accomplished in manufacturing that someone said couldn't be done. Or, perhaps there is a “manufacturing superhero” who has positively impacted your life or industry.

More information about this digital IMTS experience can be found at imts.com.

Read Next

Making Waves with Lathe Automation

After years of relying on an extensive machining cell for part production, this marine equipment manufacturer has now reduced part handling and improved quality through use of single-setup lathes and automated loading and unloading.

Read More3D Printing Creates a Window of Automation Opportunity

For this Omaha shop, periodic part inspection required an automated turning cell to pause production. Printing a plastic parts collection chute for delivery outside the cell solved this problem, and it turns out the shop has found 3D printing to be valuable in many other ways.

Read MoreAutomated Manufacturing in the U.S. Makes for a Fitting Process

An Australian company has been able to speed delivery of its popular plumbing products to U.S. customers by adding machining and assembly cells to produce brass fittings in Alabama.

Read More

.jpg;maxWidth=300;quality=90)