Three Hands Beat Two

Co-bots are a technical leap forward from the traditional industrial robot that has evolved from its introduction in the 1950s.

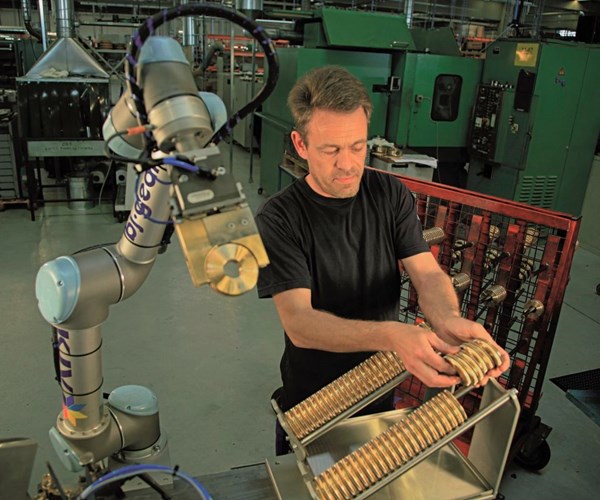

When you need an extra hand.

Three hands beat two hands is the theme of an article we published last year on application of collaborative robots (co-bots), called "Collaborative Robots for DIY Automation." At the recently completed IMTS 2016, these safety conscious helpers were part of an automation feeding frenzy that helped draw the third largest attendance in the show’s history.

Since we published this piece, co-bots have taken off in dissemination within manufacturing and proving their worth across most every industry spectrum. Co-bots are a technical leap forward from the traditional industrial robot that has evolved from its introduction in the 1950s.

With co-bots, the walls of solitary confinement required to keep machine and man at a safe distance have come down. Hyper sensor technology on these machines make human and co-bot interaction perfectly compatible and safe even in close proximity.

Now when a worker needs “an extra hand,” it’s sitting right next door.

Related Content

-

Automation in the Alps: Studer AG Unveils New Grinding Concepts

Studer AG, member company of United Grinding, held its annual press conference at its Swiss Alps location earlier this month to announce its new automatic loaders to accompany its existing grinding machines as well as other offerings and automation features.

-

Replace Repetitive Measurement With DIY Robotic Automation

After minimal training, a shop can learn how to use this robotic inspection system configured for a shopfloor application to supersede repetitive, time-consuming, high-mix gaging processes. It can then be redeployed for another application somewhere else in the facility.

-

4 Bright Ideas for Effective Lights-Out Machining

Adopting lights-out machining involves considerations when a machine shop decides to move forward with the process. Here are some tips to a successful implementation.

.jpg;maxWidth=300;quality=90)