Tool Monitoring for Complex Machining

One of the biggest challenges to tool monitoring on a multitasking machine is coping with simultaneous cutting operations. Caron Engineering (Wells, Maine) designed a system to meet this challenge.

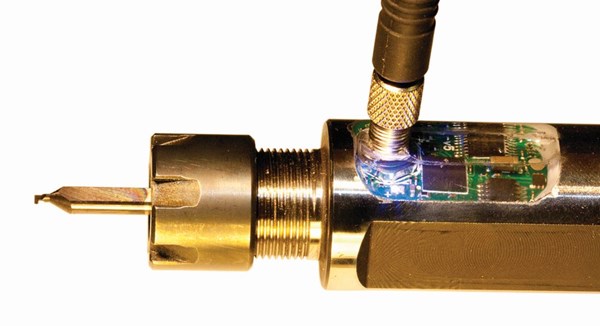

A specially designed strain gage enables small tools to be monitored effectively.

Multitasking machines are complex, yet have potential for efficiency and productivity. Completing parts in one pass across a multitasking machine streamlines production by eliminating multiple setups, avoiding errors when parts are refixtured and performing several operations simultaneously. They are also ideal for lights-out machining.

Systems designed to monitor a tool’s condition, adjust automatically for wear and capture information about the tool’s performance can be especially valuable on multitasking machines. One of the biggest challenges to tool monitoring on a multitasking machine is coping with simultaneous cutting operations. Caron Engineering (Wells, Maine) designed a system to meet this challenge called TMAC-MP, which stands for Tool Monitoring Adaptive Control for Multi-Process machines.

To learn more about this tool monitoring system and its advantages, read Tool Monitoring for Multitasking Machines.

Related Content

-

The Control’s Role in Machining Complex Parts

This company that produces medical implants finds value in the CNC for its turn-mill equipment that helps speed setups and simplify programming when producing intricate parts complete.

-

A German Machine Tool Builder’s “Second Push” Into the U.S. Market

Spinner recently has taken strides to boost its presence, service and support in the United States as well as Canada and Mexico for its multifunction CNC lathes and milling machines.

-

When a CNC Turn-Mill Doesn’t Turn

A shop in Big Sky Country uses a B-axis multitasking machine to produce complex, prismatic medical parts that require no turning complete from barstock.

.jpg;maxWidth=300;quality=90)