Autodesk Fusion 360 Unifies Design, Manufacturing Process

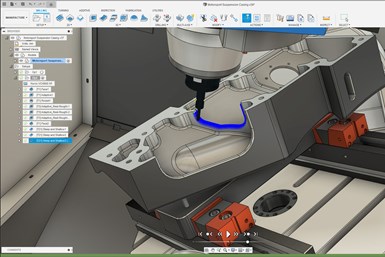

IMTS 2022: This cloud-based 3D modeling, CAD, CAM, CAE and PCB software platform for product design and manufacturing is said to help users design, engineer and manufacture products to ensure aesthetics, form, fit and function.

Photo Credit: Autodesk

Autodesk’s Fusion 360 is said to unify design, engineering, electronics and manufacturing into a single cloud-based software system. The platform’s technology extensions are said to provide access to advanced features for complex machining, generative design additive manufacturing and more.

This cloud-based 3D modeling, CAD, CAM, CAE and PCB software platform for product design and manufacturing is said to help users design and engineer products to ensure aesthetics, form, fit and function.

The company says users can engineer, design and create anything with comprehensive electronics and PCB design tools to save time and money, and get quality parts out the door faster. Recent updates include a machining extension which is said to accelerate CAM programming with powerful toolpath modification tools, enabling rapid edits without wasteful recalculations, so machining starts sooner and delivers parts faster.

The software’s advanced 4- and 5-axis simultaneous tool paths are said to improve surface finish, use fewer part setups and increase cycle efficiency. Automatic collision avoidance is said to enable safe machining of complex parts.

The part inspection extension features CAD-based and spindle-mounted probes that are designed to measure and improve the accuracy of CNC part alignment, saving time and producing better parts. Autodesk’s Certification Program offers eight role-aligned, industry-validated certifications in Fusion 360 CAD and CAM workflows.

Related Content

-

Automation Idea for Halloween?

Maybe not. But, the candy-throwing robots at MetalQuest’s Nebraska facility do enable the contract machine shop to stand out at career fairs and similar events.

-

Video: Using AR for Remote Machine Tool Troubleshooting

Augmented reality can enable service engineers to help machine shops identify and possibly remedy issues with their machines remotely, perhaps eliminating the time and cost of an on-site diagnostic and maintenance visit.

-

Piezoelectric Sensor Technology: Moving Toward more Efficient Machine Monitoring

A new system that uses simple and compact force or strain sensors, which can be integrated inside toolholders or mounted on surfaces such as spindle housings, can facilitate CNC machine monitoring.