Automated Cutting Fluid Control System for Lubrication, Cooling

Connected via Wi-Fi or LAN, this metal cutting fluid control system gives users full access to the fluid monitoring system via a dashboard which continually updates, enabling users to remotely monitor the current fluid conditions.

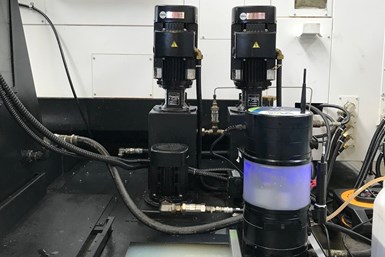

Centric’s Will-Fill automated fluid control system is said to automatically fill, refill, analyze and adjust the condition of machine cutting fluid from anywhere. The system is said to analyze and control seven critical parameters, including concentration of oil /water mix, coolant level, coolant temperature, pH levels, EC (hardness of water), oil usage and water usage.

Because every process and shop floor is different, this system is designed to enable users to establish their own predefined settings and thresholds. The system is said to maintain those settings whether users are running a 24-hour lights-out operation, traveling or away from work to ensure the machine is always running at optimal conditions.

With this system, the machine is always connected to incoming water and oil to maintain and supply the ideal mix of cutting fluid automatically, the company says. Plus, Will-Fill is said to work with any metal cutting fluid.

Once installed and connected via Wi-Fi or LAN, users have full access to the fluid monitoring system via a dashboard which continually updates, enabling users to remotely monitor the current fluid conditions. In addition, users can receive emails and alerts that can be preset to advise in real-time when the thresholds are exceeded and the system is taking corrective action. This information is captured and archived, enabling users to extract data, run reports and make informed decisions as part of an ongoing process evaluation.

By incorporating this system into a fluid management strategy, it is said users can increase productivity, improve quality of parts, reduce water and oil consumption (by not overfilling), extend life of cutting fluid, maximize your tool life and extend machine life. It is also said to increase machining performance, reduce the environmental footprint, minimize residue buildup on the machine and reduce health risks caused by contaminated fluids.

Related Content

-

FluidLynx Offers Intelligent Cooling Lubricant Automation

PMTS 2023: Motorex’s FluidLynx automated fluid management system offers controllable and traceable process reliability, while better protecting workpieces and machines, and optimizing tool life.

-

Metalworking Fluid Management and Best Practices

Cutting metal is a complex process involving many critical factors to be successful. Correctly applied metalworking fluids, including oils or coolant, is one of these critical factors.

-

Zebra Skimmers' Coolant Systems Automate Fluid Management

PMTS 2023: The Zebra Dazzle 2 system can reportedly reduce coolant usage and CNC tooling by as much as 80%.