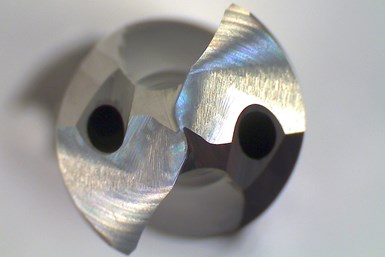

Better Edge's Drill Point Features Unique Geometry

PMTS 2023: The Bat Wing point geometry provides optimized gashing for lower thrust, polished flutes for increased chip evacuation and coolant gash channels for optimum flow.

Better Edge’s Bat Wing drill point geometry is designed for machining steels, stainless steels and irons. The patented point geometry features optimized gashing for lower thrust, polished flutes for increased chip evacuation and coolant gash channels for optimum flow, as well as a radius edge for edge strength and centering capabilities.

A proprietary edge preparation process and high-performance AlTiN coating yield greater tool life and improved process performance. According to Better Edge, recondition performance is like new, offering users optimal drill life and cost savings. Better Edge is an ISO 9001:2015-certified company located in Scottdale, Pennsylvania.

Related Content

-

CNC Turning Tips for HRSA Materials

Rough-turning, heat-resistant superalloys can be challenging. However, new carbide insert technology provides the capability to perform high-speed, high-feed roughing in a single pass.

-

Boring Head Enables Sculpture Hardware to Be Machined on a Lathe

When small job shop Ansonia Manufacturing took on a tricky hardware component job for a “live” glass art sculpture, it realized a boring head would be needed to machine the part complete on its live-tool lathe.

-

Replaceable-Insert Spade Drill Basics, Advantages

Although solid carbide and indexable-insert drills have their place in a machine shop, replaceable-insert spade drills offer specific advantages for various holemaking operations on machining centers and lathes.

.png;maxWidth=300;quality=90)