Boring Series Features Modular Components for Flexible Cutting

Walter says its Precision Boring XT tools yield high surface finishes and are up to three times more reliable and flexible than comparable models.

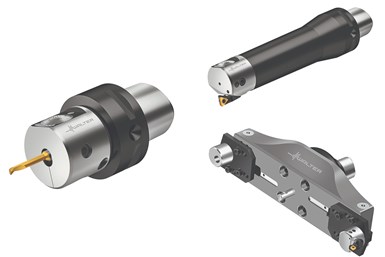

Walter Precision Boring XT B5110 (left), B5115 (top right) and B5120 Walter Precision XT boring tools. Photo Credit: Walter

Walter’s Precision Boring XT series is designed to deliver precision, as well as flexibility and high surface quality with its B5110, B5115, B5120 and B5125 boring tools.

The compay says the B5110 is well suited for fine boring of small diameters. It uses either a solid carbide boring bar option for diameters of 0.039-0.323″ (1-8.2 mm) or an indexable insert boring bar design for diameters 0.315-0.787″ (8-20 mm).The B5115 is designed for precision boring of medium range diameters of 0.748-6.575″ (19-167 mm). Unlike the B5110 which uses the boring bar design, the B5115 utilizes the cartridge-style design, as larger space is available for the tool design to accommodate the cartridges.

The B5120, with diameters of 5.827-25″ in. (148-625 mm) is said to expertly cover large diameters with its bridge and cartridge design. The bridges are made of aluminum to accommodate the weight constraints of machine tool spindles. A separate line of reduced weight boring bars in medium range diameters is also offered through B5125-LWS. The LWS stands for light weight selection.

The B5125 uses the same cartridges as the B5115 and B5120, thus reducing cost through modular use of cartridges across the systems. The precision dial for all the new systems boasts a dual inch/metric unit dial so separate tools are not necessary for global customers who work with dual unit systems.

These vibration-free tools are said to provide finish machining of precise bores (IT6–IT8) up to 6 × D, with high surface quality and are up to three times more reliable and flexible than comparable models. The company says their flexibility is boosted because these boring tools employ modular components such as cartridge holders and extensions, which are matched to the system, utilize an extensive range of indexable inserts suited for precision boring, and can be used for all material groups. The XT System boring tools are available in Capto connection as well as Walter proprietary NCT and screw-fit adaptions.

Related Content

-

Micromachining Fundamentals

A number of elements must come together to establish an effective process for machining at a micro level. Here we consider four.

-

Replaceable-Insert Spade Drill Basics, Advantages

Although solid carbide and indexable-insert drills have their place in a machine shop, replaceable-insert spade drills offer specific advantages for various holemaking operations on machining centers and lathes.

-

The Value of Tool Monitoring on Rotary Transfer Machines

By using a tool monitoring system, shops can save costs associated with machine maintenance and downtime for tool changes while increasing cutting performance.

.png;maxWidth=300;quality=90)