CappsNC Enables Programming Offline

CappsNC software enables programming offline and runs any CNC machine tool as a CMM using measurement data to automatically improve the machining process.

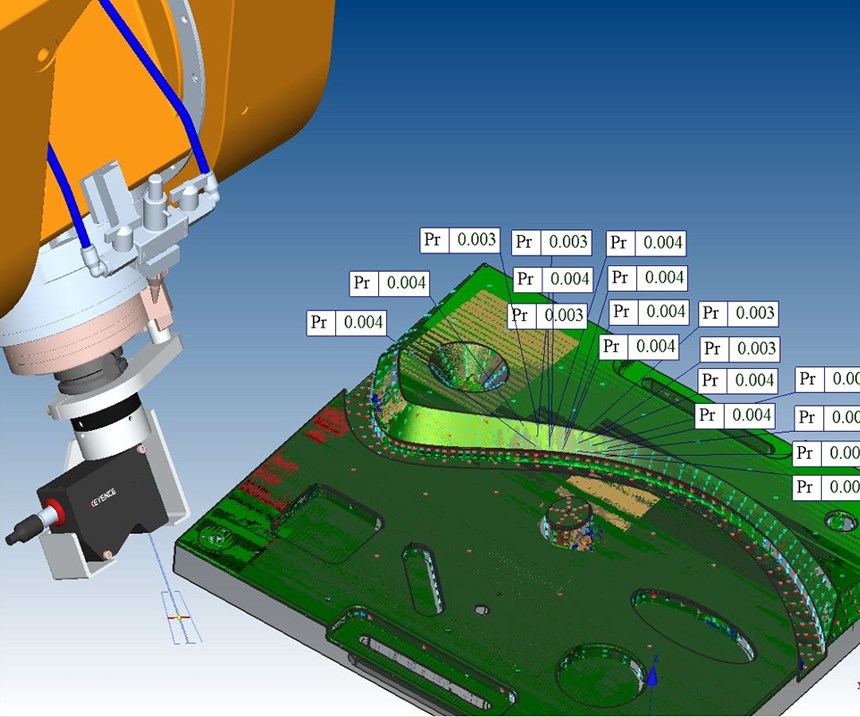

To perform the complex mathematical calculations required for the metrology-based real time decision making, a CMM software needs to be integrated within the manufacturing system. CappsNC, from Applied Automation Software Inc., programs any machining center to perform advanced measurement, metrology and GD&T calculations using the standard DMIS language. Offline programming with automatic collision avoidance and five-axis path generation enables programming of machine configurations including multi-axis, mill-turn machines, according to the company.

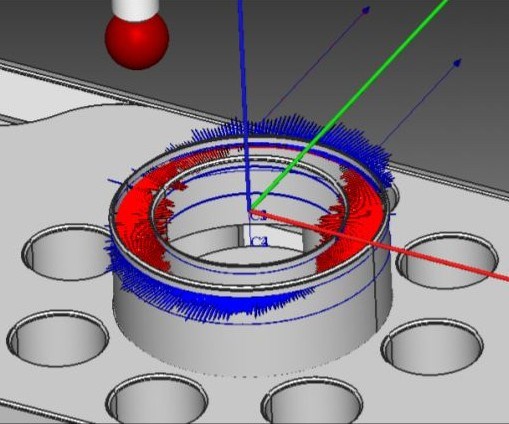

A CAM-style programming environment with realistic tool virtual model, simulation capabilities, automatic path generation with collision avoidance, and complete geometrical fitting and tolerancing functionality are provided within the software. Multi-view graphics with UI programming environment makes it easy to create programs for any machine tool configuration.

The software connects with most machine tool controllers with a real time direct interface. A G-code program is created from the DMIS program so the tool can be used by the operator or by an automation cycle. Live 3D simulation is displayed and calculations are performed as soon as data are collected. The calculated metrology characteristics are used as a part of the on-the-fly decision making and written back to the machine tool controller as a part of the adaptive cycle.

According to the company, this software uses its own generated macros and doe not require OEM generated macros. This enables the software to be probe brand independent and works with the existing probes available on the machine. The software can also work with different probe types, including kinematic probes, strain gage probes, analog probes and blue light laser sensors.

While the software can operate any machining center, the goal is much bigger than simply preforming on machine measurements by providing pre-process, in-process and post-process benefits.

Related Content

-

Precision Machining Technology Review December 2022: Measurement

Production Machining’s December measurement showcase includes some of the latest technology from Haimer, Hamar, Sunnen, OGP, Marposs and Zeiss.

-

PMTS 2023 Product Preview: Measurement

Learn about some of the latest measurement solutions that will be on display at PMTS 2023.

-

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

.jpg;maxWidth=300;quality=90)