An intuitive CMM operator interface makes it easy for machinists to call up and begin a measurement routine. Photo Credit: WLR Precision

The UK’s WLR Precision Engineering in Wilford, Nottinghamshire, is a contract manufacturer that initially produced aerospace prototype and test parts. Today, the company has grown to develop and manufacture products for oil exploration, pharmaceutical and motorcycle industries, among others.

It continues to invest in new machining technology and has a wealth of measurement equipment as some jobs require 100% inspection. In fact, the latest two coordinate measuring machines (CMMs) from LK Metrology include intuitive software to enable production machine operators as well as quality inspectors to operate them and easily access measurement reports.

The first of these, an AlteraS 15.10.8, was purchased in 2015. This CMM was acquired largely due to a steep increase in components ordered by key customers coupled with a requirement for more comprehensive inspection and detailed reporting. Soon afterward, a customer in the defense industry approached the company with a similar requirement for the provision of traceable measurements and certified reports covering the supply of critical, matched components.

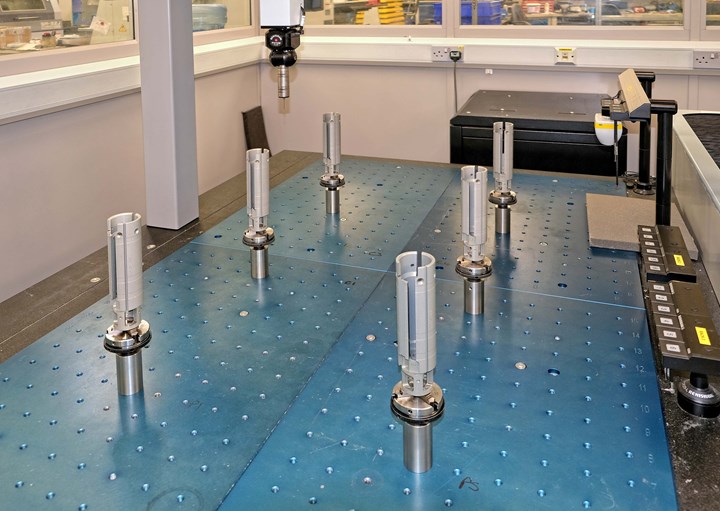

According to WLR, a major benefit of this CMM is its large table area — approximately 1.0 × 1.5 meters — which can accept up to 12 identical components at a time for batch inspection, instead of just one as on the shop’s older CMMs. Typically, five batches can be inspected during a day shift with a load time of about five minutes between each batch.

After components have been fixtured, an inspector presses a button and every part is measured in a single, automatic cycle, the longest of which is two hours. The inspector is then free to work elsewhere on other metrology equipment for most of the day and the time the inspection will take is known exactly. Efficiency is much increased compared with the former method, whereby an inspector was committed to sitting by a CMM all day loading each part individually prior to every automatic measurement cycle, all of which took an indeterminate amount of time that was longer than the equivalent automatic batch cycle.

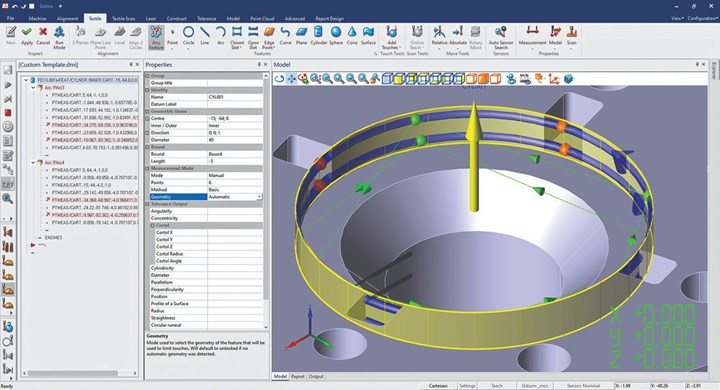

In addition, with the previous process, subsequently preparing reports by hand for 12 inspected parts typically took three hours, which was not just time-consuming but also tedious. Now, LK Metrology’s Camio CMM software is used to perform the task automatically. A comprehensive, graphically supported inspection report is generated on an entire batch in a matter of minutes, covering 30 to 40 critical dimensions on each part, complete with color-coded content in the event of any nonconformance. The report data is exported, via a CSV-type file formatted by WLR, directly into an Excel spreadsheet.

All these advantages have led to a considerable enhancement in inspection and reporting efficiency at WLR, enabling the company to accommodate a surge in orders from several customers. It has also helped the company cope with a steadily increasing level of business across the board that has seen six or so parts ordered by some customers placed three or four years ago increase by up to 10-fold today. This has been managed without employing any extra people, thanks to automation in the inspection room and on the shop floor.

By May 2021, a further increase in batch measuring capacity was needed. A requirement was also introduced for in-process inspection of a particular family of components for one customer. This time, a smaller LK AlteraS 10.10.8 with a working volume of 1,016 × 1,016 × 813 mm was purchased together with the latest Camio 2021 software.

Fixturing multiple parts at once on a CMM’s table enables long stretches of unattended measurement. Photo Credit: WLR Precision

Both CMMs were delivered with LK Launchpad, an icon-driven, touchscreen operator menu, and a network of viewing screens and tablets. The simplified operator menu lists all the available inspection programs and the exact position the part should be placed on the CMM’s table for inspection, giving operators the confidence to perform measurement tasks in just a few clicks. It also enhances flexibility and opens the system for use by nonspecialist CMM operators. Measured results and automatically-generated reports can be shared between screens, tablets and other networked devices for easy access and viewing from any location.

The intuitive graphical interface enables not only the two WLR quality personnel to load parts singly or in batches of up to six at a time but also the 10 day- and 5 night-shift machine operators.

A simplified operator menu lists all the available inspection programs and the exact position the part should be placed on the CMM’s table.

Launchpad makes it simple to load the correct program for inspecting a component, which is easily identified from stored data, with details called up via graphical menus and icons on a screen positioned by the CMM. The operator can locate the component by selecting the customer by name, via the part category or by directly calling up the part itself, complete with details of the machining process.

Setup on the CMM is straightforward, assisted by 12-mm-thick aluminium fixture plates predrilled with a grid of holes at a 50-mm pitch across the unit’s granite table. The operator simply places a component in a numbered location on one of the fixture plates, as indicated by the Launchpad graphic, and starts the measuring program by pressing a button on the touchscreen.

For convenience, the same inspection results that appear on the screen adjacent to the CMM are also available on networked tablets used by machinists on the shop floor and the information can also be shared with other devices. It enables more robust inspection and less downtime as well as creating an environment where machinists become invested in the procedure. The next step will be to include functionality that enables operators to be alerted via their tablet when the measuring cycle is complete, in case they are away from the CMM.

CMM Programming From CAD

Another capability, one that was introduced to the WLR with the first LK Metrology CMM, is the ability to program the machines directly from CAD. Previously, it was sometimes necessary to produce a first-off component for a customer in up to six operations on a succession of machine tools, then take the part repeatedly to the inspection department to be measured and subsequently corrected, if necessary. After it had been finished-machined, the component was used as the basis for teaching a measuring program into one of the older CMMs. Now, in the same way that a part program is derived directly by a CAD/CAM system from a CAD model of a customer's component, the DMIS inspection cycle for the AlteraS CMMs can be created from the same CAD model using Camio software in advance of the first part being produced.

The latest Camio 2021 CMM programming software is said to have been updated to increase inspection productivity, improve the quality of data collected and gain better insight into the components being measured. Photo Credit: LK Metrology

Programming time is subsequently faster than before, but perhaps the biggest advantage is that programming is completed offline. That way, the CMM is not occupied, enabling part inspection to continue uninterrupted. Together with the benefit of multisensor capability using a Renishaw SP25 scanning probe or a Nikon LC15Dx laser scanning head instead of a touch-trigger probe, for example, measuring throughput has been increased. All inspection routines for both CMMs are now prepared this way in Camio, which performs not only programming but also analysis of the captured data and automatic reporting of the results.

WLR says the new measuring processes can be used by personnel with a wide range of experience levels. The high degree of automation, plus the ability to increase speed by scanning as well as touch-probing, have helped save time and open inspection bottlenecks.

Related Content

Video Tech Brief: Quality Control is Using the Right Software

This machine shop’s mapping software program runs on its gaging system to increase the accuracy of the probe’s tolerance measurement on the thin-walled aluminum tube machined by the shop.

Read MoreHow Well do You Know Granite Surface Plates?

Here are some tips for choosing, maintaining and customizing a granite solution that will best meet your shop’s particular inspection needs.

Read MoreReplace Repetitive Measurement With DIY Robotic Automation

After minimal training, a shop can learn how to use this robotic inspection system configured for a shopfloor application to supersede repetitive, time-consuming, high-mix gaging processes. It can then be redeployed for another application somewhere else in the facility.

Read MoreDoes a Scanning Probe Make Sense on a Swiss-Type?

Swiss-types have limited tooling capacity, but there can be advantages to giving up some of that capacity to take advantage of a touch probe — in fact, a scanning probe — to enable in-process part measurements.

Read MoreRead Next

Vision Metrology for Medical

Understanding best practices and the options available with vision measurement systems is particularly important when inspecting complex medical components having stringent traceability requirements.

Read MoreManufacturing Automation Beyond Robots at PMTS

A variety of automated machining and manufacturing processes — including, but not limited to, robotics — that can enable shops to become more efficient were on display at the recent Precision Machining Technology Show.

Read MoreDoes a Scanning Probe Make Sense on a Swiss-Type?

Swiss-types have limited tooling capacity, but there can be advantages to giving up some of that capacity to take advantage of a touch probe — in fact, a scanning probe — to enable in-process part measurements.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)