Ceratizit's Control System Increases Process Security

Eastec 2023: The ToolScope monitoring and control system can reduce cycle times up to 15% and, with wear monitoring, optimize tool life and provide additional tool reserve usage up to 30%.

Ceratizit’s ToolScope and KOMtronic U-axis systems, as well as its line of indexable milling tools and range of Klenk solid-carbide drills are designed to improve machining efficiency.

The Ceratizit ToolScope monitoring and control system consists of a suite of specialized modules — process control, machine protection, digitization and documentation — aimed at measuring and optimizing particular aspects of machining operations. According to the company, ToolScope can increase process security by as much as 25%; reduce cycle times up to 15%; and, with wear monitoring, optimize tool life and provide additional tool reserve usage up to 30%.

Ceratizit’s freely programmable KOMtronic U-axis system makes contouring and turning operations possible on non-rotationally symmetrical parts. When combined with custom-made front tools and the optimum selection of inserts, the system successfully performs contours in bores as well as external machining operations. This capability enables shops to reduce production time, improve surface quality and achieve greater accuracy of form. Additionally, the system reduces the amount of required tools and eliminates the need for clamping devices for finish machining on turning machines.

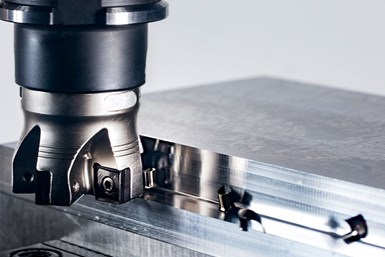

Ceratizit’s MaxiMill 491 and MaxiMill 273 indexable mills are designed for part milling performance and flexibility. The new MaxiMill 491 has eight usable cutting edges per its newly expanded 9-mm insert size, a precise 90-degree profile and a durable nickel-coated tool body. The cutter is designed for all shoulder and full-slot milling applications. With 16 usable, axially adjustable cutting edges, the MaxiMill 273 Shell Face Milling Cutter combines the advantages of positive and negative inserts in one cutter, reportedly ensuring stability and cost-effectiveness while reducing vibration for superior surface finishes.

The Ceratizit Klenk product line targets the aerospace industry and encompasses advanced rotating tools for drilling. Many of these products are custom-made for customers and used in machining carbon fiber-reinforced plastic (CFRP), titanium, aluminum and steel components.

Look for these and other shop management software options at Booth 5474 at Eastec 2023.

Related Content

-

Avoid the 7 Deadly Sins of Manufacturing

Identifying and preventing these manufacturing sins will reduce or eliminate unnecessary waste, improve efficiency and productivity as well as protect profitability and cash flow.

-

PMTS 2023 Product Preview: Shop Management Software

Learn about some of the latest shop management software solutions that will be on display at PMTS 2023.

-

ProShop Provides ERP Technology to Purdue Engineering School

The ProShop Digital Ecosystem will be used as the inventory management and ERP system at Purdue University’s Industrial Engineering School.