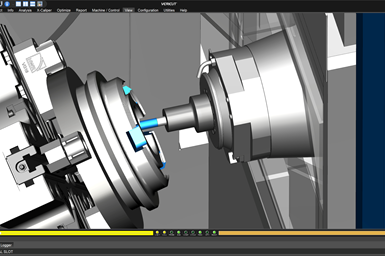

CGTech Simulation Software Optimizes Machining Operations

Eastec 2023: Vericut software detects errors and potential collisions in NC programs prior to running them on machines for the first time, thereby enabling programmers to send programs to a machine with the confidence it will run without incident.

CGTech’s Vericut simulation, verification and optimization software is capable of simulating multiple types of machining operations such as traditional milling and turning to additive or hybrid manufacturing, as well as composites.

Vericut detects errors and potential collisions in NC programs prior to running them on machines for the first time, so programmers can send programs to a machine with the confidence they’ll run without incident. According to CGTech, the simulation reduces or even eliminates the manual prove-out process, streamlining the manufacturing timeline and freeing up additional machining capacity.

In addition to its core simulation capabilities, Vericut also offers more modules to meet different needs. Force is Vericut’s physics-based optimization module that dynamically adjusts feed rates and spindle speeds based on the current cutting conditions to reduce machining times, provide better component finishes and extend tool life. Users can choose to prioritize more efficient machining to increase throughput, or prioritize tool life for more difficult cuts.

One of Vericut’s newest modules is CNC Machine Connect. This module enables users to conduct a pre-check, verifying that the physical machine setup matches what was simulated in Vericut. If different values are detected, operators can quickly run the simulation with the updated parameters to verify there are no issues or errors without having to send the program back for corrections.

Look for these and other shop management software options at Booth 2023 at Eastec 2023.

Related Content

-

Paperless Parts' AI-Powered Automation Tool Streamlines Quoting

Wingman is powered by a secure AI model developed to extract critical information from quote packages so that estimators can work faster, automate administrative aspects of setting up quotes and minimize the risk of missing important details.

-

Sustainability Analysis Tool Aids Data-Driven Decision-Making

Can increasing productivity and reducing carbon emissions go hand-in-hand? For its high-volume machining customers, Sandvik Coromant offers a tool for data collection and comparison to aid sustainability-minded process decisions.

-

ERP Software Enables Manufacturers to Maximize Operational Efficiencies

PMTS 2023: JobBoss2 from ECI Software Solutions assists manufacturers with decision-making and reveals opportunities for growth and cost savings.

.jpg;maxWidth=300;quality=90)