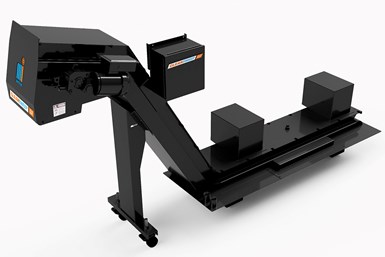

Chip Conveyor Provides Both Chip Handling, Coolant Filtration Functionality

PMTS 2023: The CleanSweep G2 is a self-cleaning conveyor designed to help operators eliminate the need for frequent coolant tank cleaning and maintenance.

Mayfran International’s CleanSweep G2 expands on the functionality of the original CleanSweep-RM chip conveyor and aims to meet the changing needs of advanced machine tool applications. With the ability to handle higher coolant flows and a variety of fines, chips and turning types, the company says the CleanSweep G2 is a versatile solution that can help machine tool OEMs and operators reduce labor and material costs, leading to more efficient operations overall.

The CleanSweep G2 is a self-cleaning conveyor, helping operators eliminate the need for frequent coolant tank cleaning and maintenance. Under regular operating conditions, the CleanSweep G2 can help most customers reduce necessary coolant tank cleanouts to once per year. The results are increased machine uptime and extended coolant, pump and tooling life.

The conveyor also features a compact design to save floor space and minimize trip hazards. It has an inner handling system designed to reduce chip buildup in the conveyor. Mayfran also says the Clean Sweep G2 features effective coolant cleaning to a 150-micron nominal. The equipment comes with a heavy-duty belt with hardened components to provide long-term reliability.

Alongside the CleanSweep G2, Mayfran’s G2 “retrofit ready” hinged belts and conveyor retrofit kits are also available, enabling customers to upgrade their machines when they are ready.

Related Content

-

Get to Know the PMPA at PMTS 2023

The Precision Machining Technology Show provides the chance to see what membership in the Precision Machined Products Association offers at the association’s co-located National Technical Conference.

-

Integrated CAD/CAM Software for Maximum Efficiency

PMTS 2023: This software solution is said to enable users to take advanced mill-turn and Swiss-type machining to new levels of speed, efficiency and simplified programming.

-

Compact Micro Turn-Mill for Small Precision Parts

PMTS 2023: The Spinner PD-CNC lathe can achieve high levels of precision due to its high-precision spindles, pneumatic clamping cylinders with programmable clamping force, ultraprecise ball screws, and hardened and ground sliding vibration-damping guideways.

.jpg;maxWidth=300;quality=90)