Clamping Disks for Chucks and Mandrels Enable Low TIR

Clamping discs for its flange chucks and flange mandrels feature true running accuracies of just 10 microns, and offer greater loading clearance and longer operating life.

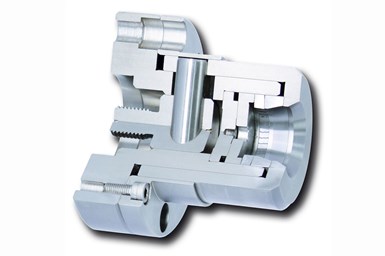

Ringspann bonded disc pack flange chuck with 15-degree clamping discs for the high-precision external clamping of cylindrical workpieces.

Ringspann’s 15-degree clamping discs feature true running accuracies of just 10 microns, and offer greater loading clearance and longer operating life. The discs are essential components for Ringspann’s standard clamping systems — LAFF flange chucks and LBDF flange mandrels — which are often used for machining cylindrical gear components.

The clamping disks are combined into ring-shaped and pre-stressed packages between 4.0 and 20 mm wide, depending on the number of discs. Their size follows the clamping diameter required for machining the workpiece. This ranges up to 170 mm for chucks and 200 mm for mandrels.

Thanks to the precise, uniform 360-degree expansion of the flat tapered clamping discs, the torque is always transmitted to the workpiece with a consistent pressure force. This homogeneous clamping protects the surfaces of the component and makes the LHFF flange chucks and LIDF flange mandrels well suited for machining thin-walled, deformation-sensitive precision components. The permissible workpiece tolerance of these clamping tools ranges up to IT13, and for most sizes, even up to IT14.

The improved total indicator reading (TIR) gives users two crucial advantages without compromising on accuracy. It enables significantly larger diameter changes to provide a more comfortable loading clearance and gives the clamping discs a considerably longer service life thanks to more significant wear reserves.

The LHFF flange chucks and LIDF flange mandrel produced with the TIR-optimised 15-degree clamping discs are well suited for gentle clamping of sensitive workpieces and machining tasks with very high demands on machining accuracy. They also give users a high-precision solution for centering, aligning and clamping cylindrical workpieces whose inner and outer surfaces have already been pre-machined for downstream applications, where precision and security in clamping become paramount.

Related Content

-

Broaching Tool Technology For Lathes Used to Slot Inconel Parts

This shop finds value in using an indexable-insert-style broaching tool to create blind-hole slots in heat-treated Inconel aerospace parts on a CNC lathe.

-

German Project Yields Three New Medical Machining Processes

Recent research has resulted in a new mix of high-speed turn whirl milling, polygon turning and rotational turning for manufacturing medical bone screws and out-of-round nails.

-

Replaceable-Insert Spade Drill Basics, Advantages

Although solid carbide and indexable-insert drills have their place in a machine shop, replaceable-insert spade drills offer specific advantages for various holemaking operations on machining centers and lathes.

.jpg;maxWidth=300;quality=90)