Zero-Point Clamping System Offers Increased Flexibility

PMTS 2023: The Combi series features an integrated 52- and 96-mm zero-point grid which enables users to clamp the complete range of applicable Lang vises in the same zero-point unit.

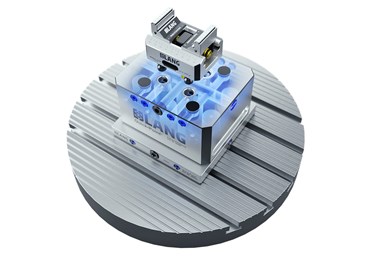

The Combi series offers two different grid dimensions in one zero-point unit. Photo Credit: Lang Technovation

Lang Technovation’s 52- and 96-mm Quick-Point clamping systems offer a 2-in-1 solution for greater flexibility, high precision and shorter setup times. The Quick-Point is said to combine all the features that make a zero-point clamping system special. A new series within the Quick-Point zero-point clamping system takes this to the next level and enables users even greater flexibility in their manufacturing needs.

The Combi series offers two different grid dimensions in one zero-point unit with selected plate types from Lang Technovation’s zero-point clamping system now available as a combo version. The Combi series with integrated 52- and 96-mm zero-point grid enables users to clamp the complete range of applicable Lang vises in the same zero-point unit.

The flexibility of the mechanical zero-point clamping system is further increased in terms of application versatility, while at the same time reducing the time required for changeovers. In smaller machine tools with little travel in the Z-direction, the elimination of an additional adapter plate can also be helpful.

The combo plates are available in square and round designs, as well as in a version with a clamping edge. Lang Technovation also offers its combo solution as a 5-axis riser and as a twin base for 3-axis machines and rotaries.

Related Content

-

Why Are We Writing About a Shop Making Custom Baseball Bats?

I recently learned about a 153-year-old manufacturer that has produced billions upon billions of precision, metal pins which started another business making one-off wooden baseball bats. (Like I asked it to do for me and you’ll see at this year’s Precision Machining Technology Show). Here I explain why it’s worth the time to read that article.

-

Sita’s CleanoSpector Measures Part Cleanliness

PMTS 2023: Handheld measuring device checks for cleanliness of parts to assure product quality as well as prior to follow-up processes.

-

KGT Live Tool Replacements for Swiss Machines

PMTS 2023: It is said the KGT tools are constructed with top-of-the-line gears and high-quality bearings, providing machinists with a high-performance result and a long tool life that are comparable to OEM products.

.png;maxWidth=300;quality=90)