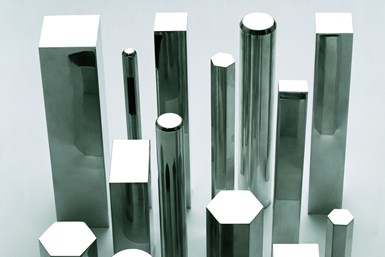

Eural’s Lead-Free Aluminum Alloys Offer Machining Benefits

Eural’s Cutting aluminum alloys comply with RoHS directive 2018/740/EU.

Eural USA Inc.’s lead-free cutting aluminum alloys 2033, 2077, 6026 are designed to meet RoHS directive 2018/740/EU and offer a variety of machining benefits. According to the company, Alloy 6026 is lead-free and designed to ensure good chip forming, good corrosion resistance, high mechanical properties (Rm ≥ 53.7 ksi) and excellent surface finishing after turning. It is also well suited for hot forging purposes. The 6026 lead-free alloy is suggested as an alternative to alloy 6061, 6020 and 6262A as wells as alloys 6042, 6262 and 6064A which have Pb ≥ 0.1%. Eural’s 2033 lead-free alloy is said to provide good machinability due to a very thin chip forming, high mechanical properties (Rm ≥ 53.7 ksi), excellent surface finishing after turning, and good anodizing and weldability aptitude compared to alloy 2011 which is Pb ≥ 0.2%. The lead-free 2077 alloy enables strong free cutting and excellent machinability, and has very high mechanical properties (Rm ≥ 72.5 ksi) which are well-suited for hot forging because it does not require further heat treatment to reach and fix mechanical properties. The 2077 alloy can replace aluminum alloys 2014, 2014A, 2017, 202 and 7075, and is a lighter alternative solution to other metals, such as brass and certain kinds of steel.