Heidenhain Touch Probe for Soft, Delicate Workpieces

Heidenhain’s TS 750 touch probe operates with high-precision pressure sensors with force analysis for generating the trigger pulse.

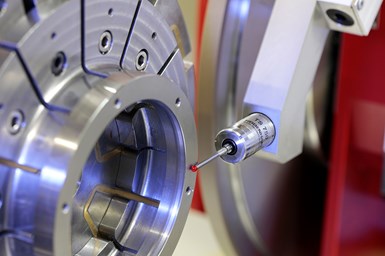

TS 750 high-precision touch probe features a low probing force for working with soft or delicate workpieces. Photo Credit: Heidenhain

Heidenhain’s TS 750 touch probe is designed for high-precision, in-process workpiece measurement in grinding machines and lathes. The company says the probe is extremely durable and offers the ability to state the reproducibility of its jobs at increased probing speeds better than most competitors. It is said the touch probe’s low probing force is a benefit when working with soft or delicate workpieces.

The touch probe operates with high-precision pressure sensors with force analysis for generating the trigger pulse. The forces that arise during probing are processed electronically. This method is said to deliver homogeneous, 360-degree probing accuracy. It offers high probing speed of up to 1 m/min and does not require a minimum speed.

Also, due to its low probing forces of approximately 1.5 N (axial) and 0.2 N (radial), the TS 750 can attain high probing accuracy (±1 micron) and repeatability with almost no effect on the measured object, the company says. Only on further deflection do the forces of the springs take effect until the machine stops.

The company says the probe continues to deliver reliable measurements after prolonged use — even after 5 million probing cycles. The TS 750 touch probe is still highly accurate with a probing repeatability of down to 2 σ ≤ 0.25 micron at its high probing speed.

Related Content

-

Video Tech Brief: Quality Control is Using the Right Software

This machine shop’s mapping software program runs on its gaging system to increase the accuracy of the probe’s tolerance measurement on the thin-walled aluminum tube machined by the shop.

-

Streamlining Part Measurement, Data Collection Processes

When collecting measurement data automatically with a wireless data collection system, manual errors can be eliminated ensuring data accuracy and traceability.

-

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.