Hypertherm Production Manager Module Offers Auto Data Capture

Software module displays real-time production data so team members across an organization can track the job order status, production schedules and pending inventory requirements.

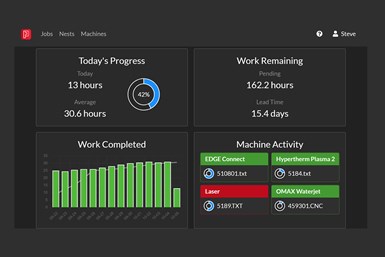

The Hypertherm Production Manager module has an intuitive dashboard view to provide production stats and trends in one view. Photo Credit: Hypertherm

Hypertherm’s Production Manager is an optional module for its ProNest advanced CAD/CAM nesting software which is a web-based module designed to improve productivity, maximize machine uptime, boost on-time delivery and increase material utilization.

Production Manager is said to seamlessly integrate with Hypertherm’s Edge Connect CNC to automatically capture machine data without the need for operator intervention. In addition, it displays real-time production data so team members across an organization can track the status of job orders, the production schedule and pending inventory requirements.

It also has an intuitive dashboard view to provide production stats and trends in one view. Color-coded status alerts help users quickly understand the on-screen information, while an interactive display enables users to drill down for additional insight.

Real-time machine data from the CNC is transferred to Production Manager. This enables users to track job progress from pending to in-production and actual completion time, making it easier to respond to customer inquiries and forecast the production schedule.

The software also offers flexible intervention to cancel or hold orders to add or remove parts based on last-minute changes. Users can view machine backlogs and ensure loads are evenly distributed across cutting machines in a way that optimizes the production schedule.

Users also have remote access, making it easy to access Production Manager via a computer, mobile phone or tablet anytime and anywhere users have a secured network or VPN connection.

Related Content

-

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

-

High-Production Multitasking Becoming More Flexible

Rotary transfer machines remain well-suited for high-volume production, but are now more accommodating to smaller batch sizes.

-

Starting Small with Automation

Quick-change workholding and flexible robotic automation started this small shop on the path to success.