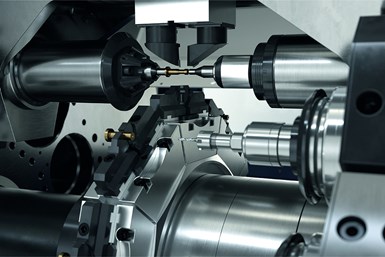

Independent Turning Cell Enables High Concentricity Precision

PMTS 2023: The RV 10 Flexmaster rotary transfer machine’s precision turning cell (PTC) is integrated in the machine as a disconnected turning cell and is free of the drive and machining factors that affect the other stations.

Winema says its precision turning cell (PTC) within its RV 10 Flexmaster rotary transfer machine enables users to machine the entire external contour of a workpiece without positioning errors, accurate to a micron level. The robust PTC is integrated in the machine as a disconnected turning cell and is free of the drive and machining factors that affect the other stations. With the PTC, the company says users can achieve the highest levels of concentricity precision with internal and external turning.

As a closed, internally rigid design, the PTC can transfer the workpiece into an independent coordinate system where it can conduct a turning process in isolation. The vibration-damped cast design disconnects the turning process from the machining factors that affect the other stations. By turning between tips, concentricity requirements that used to be critical can be manufactured without any problem down the entire length of the workpiece.

If the workpiece is held in a collet chuck by the PTC, tight positional tolerances can also be maintained between external and internal contours, all within a reliable process context. Two turning tools with Capto interface are integrated in every PTC. Three PTCs can be used in each RV10 Flexmaster. This offers users the advantage of fast rotary transfer with the possibilities of an automatic lathe — combined in one machine.

The PTC features a vibration-proofed cast construction. It offers the benefits of complete machining of outer contour; internal operations as well; and highest concentricity when turning between centers.

Related Content

-

Moen’s Flowing Success with Rotary Transfer Technology

The popular faucet manufacturer has adopted new CNC rotary transfer equipment to produce valves for its new generation of Widespread faucets.

-

Rotary Transfer Technology Becoming More Flexible

This rotary transfer machine platform, which enables shops to reconfigure equipment to change over to new jobs as needed, is said to be effective for batch sizes of only 50 parts.

-

CNC Rotary Transfer Machine Features Ballscrew Electromechanical Tooling Units

A CNC rotary transfer machine, a newly developed machine platform, is said to offer high rigidity, flexibility and accuracy for a range of high-volume, precision-machining applications.

.jpg;maxWidth=300;quality=90)