Industrial Fiber Laser Solutions for Marking, Traceability

IMTS22: Dapra’s latest industrial-grade fiber laser marking and engraving technology is said to provide reliable performance, fast cycle times and outstanding flexibility to fit any manufacturing environment.

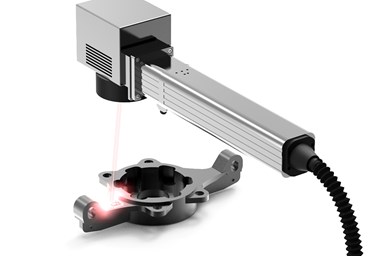

Photo Credit: Dapra Corp.

Dapra Marking Solutions’ latest industrial-grade fiber laser marking and engraving technology is said to provide reliable performance, fast cycle times and outstanding flexibility to fit any manufacturing environment — from standalone workstations to production line integration.

Its Datamark FL Series laser markers offer precise, repeatable, noncontact marking of metals, alloys and most plastics, the company says. Available with Q-switched and MOPA-fiber laser sources from 20 to 50 W, these systems are said to be capable of everything from high-contrast annealed heat marks with no surface disruption to the crisp engraving of both basic text and complex patterns at depths exceeding .004".

FL Series markers can be mounted in open Class 4 workstations or Class 1 safety enclosures, with a programmable Z-axis, optional rotary D-axis and integrated bar code reading and verifying technology. Dapra says they are designed for easy integration into robotic cells, production lines and other highly engineered solutions to support modern manufacturing environments.

Every system ships with the Datasoft Pro Windows software suite, supporting easy logo import, serialization, date coding, Data Matrix and QR codes, UID and UDI syntax and much more. With an icon-based, WYSIWYG interface, the software is said to offer all the tools to meet challenging marking requirements.

.png;maxWidth=300;quality=90)