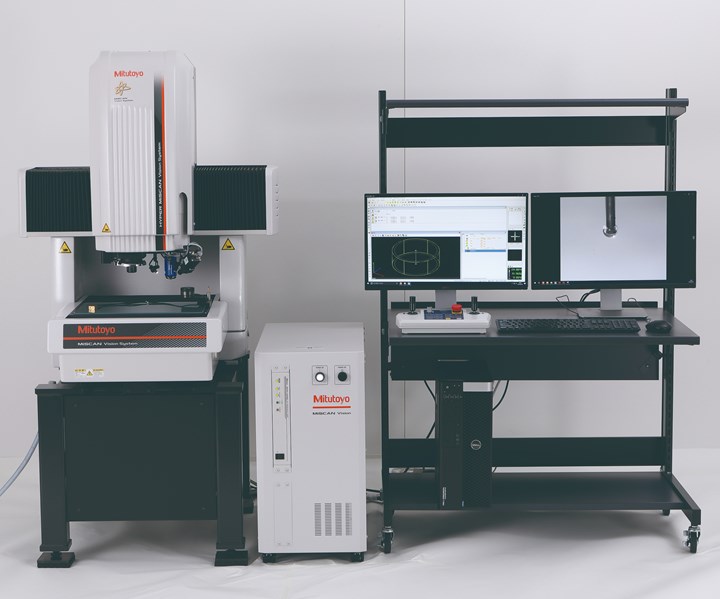

Mitutoyo's Miscan Vision System Suitable for Difficult Imaging

The Miscan uses autonomous scanning, covering micro-form to large workpieces. It can use styli as small as 125 microns diameter to measure microscopic workpieces.

Mitutoyo America Corp.’s Miscan Vision System is a multiple sensor microscopic-form measurement system. It uses combined coordinate measuring machine and vision measurement system technology with a micro-form scanning probe.

The Miscan uses autonomous scanning, covering micro-form to large workpieces. The MPP-NANO probe can use styli as small as 125 microns diameter to measure microscopic workpieces. The SP25M scanning probe is also supported to measure small and large-sized workpieces and features.

The system uses the same image head as Mitutoyo’s Quick Vision measuring system. The Quick Vision Apex lighting system is also incorporated, providing multiple lighting functions and evaluation software. The system also measures miniature optical tubes used in micro camera arrays.

The MPP-NANO can determine the contour of high degree aspheric lenses used in vehicle-mounted cameras. Mitutoyo says the probe works with Miscan to scan microscopic gear teeth by entering each nominal using Gearpak, the company’s gear teeth evaluation software. It evaluates the tooth profile error and tooth trace error. Miscan and MPP-NANO can also find the inner diameter of nozzles and draw dies without destructive measurement, using the stylus on holes with a maximum aspect ratio of 17:1.

Related Content

-

Automation in the Alps: Studer AG Unveils New Grinding Concepts

Studer AG, member company of United Grinding, held its annual press conference at its Swiss Alps location earlier this month to announce its new automatic loaders to accompany its existing grinding machines as well as other offerings and automation features.

-

Unattended Production Takes More Than the Most Capable CNC Machine

Process planning and reliable peripherals are key to successful lights-out manufacturing.

-

High-Volume Machine Shop Automates Secondary Ops

An Ohio contract shop added a compact, self-loading CNC lathe to perform unattended secondary ops on a part for a key customer rather than running it on a manually loaded chucker.

.jpg;maxWidth=300;quality=90)