Modular Filtration Systems Offer Flexible Configurations

IMTS 2022: The Flex G Series of modular filtration systems are designed as cost-effective systems featuring pre-engineered modules that ensure fast, easy, flexible filtration configurations.

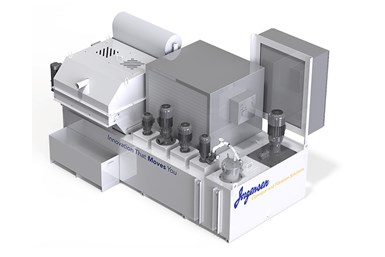

Photo Credit: Jorgensen Conveyor and Filtration Solutions

Jorgensen Conveyor and Filtration Solutions’ FlexFiltration line includes the Flex G Series of modular filtration systems, which the company says are cost-effective systems featuring pre-engineered modules that ensure fast, easy, flexible filtration configurations and add value for virtually any application.

The systems are said to efficiently remove fine chips and grinding sludge to achieve coolant clarity down to 10 microns or less. They are especially well suited for challenging applications with materials that range from cast iron, steel and aluminum to composites and plastics, the company says.

Pre-engineered base configurations and numerous options are said to enable quick construction of FlexFiltration systems to meet specific coolant flow requirements. Standard, low-profile and stainless-steel tanks are said to make these systems well suited for machine tool OEMs and regular end users. Other modular options that complete a system include high-pressure pumps, auxiliary pumps, tramp oil skimmers, coolant chillers, heat exchangers, liquid level sensors, temperature sensors and the ability to control/interface with existing pumps and other equipment.

Jorgensen’s Flex G Series systems feature gravity media filters. The gravity media filtration option is the first one available in the FlexFiltration product line. Gravity filters are offered in 30, 60 and 90 gpm options, and come standard with low media roll detection, no media alarm sensor and automatic roll advance. A variety of different disposable cloth medias are also available based on specific applications. Additional primary filtration options including bag filtration, cyclonic and permanent media types will soon be offered.