Quoting Platform Extracts, Annotates PDF Data for Improved Estimates

Paperless Parts’ enhanced quoting platform unlocks PDF files commonly shared with RFQs and makes the technical data within them more accessible and actionable.

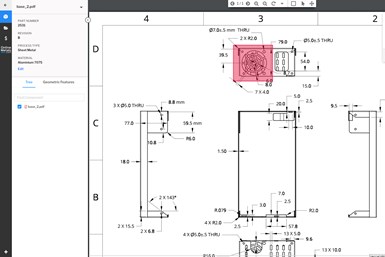

Paperless Parts' enhanced quoting platform. Photo Credit: Paperless Parts

Paperless Parts enhances its quoting platform for job shops with a PDF feature that unlocks PDF files commonly shared with request for quotes (RFQs) and makes the technical data within them more accessible and actionable.

The PDF feature extracts and annotates the PDF data for improved quoting, which helps manufacturers better understand part intricacies, improve estimation accuracy and reliably open the quoting process beyond estimators. As a result, job shop manufacturers and fabricators can turn quotes around faster, and estimates are more accurate and consistent.

RFQ files are commonly made up of multiple 2D CAD drawings, many of which may have incomplete data labels, handwritten annotations or outdated details. Providing a quote or estimate based on these static and incomplete files can be time-consuming and difficult to do accurately.

Paperless Parts says its PDF quoting feature enables customers to use those same PDF files and the data within them in new, more valuable ways. First, Dynamic Measurements enables quick interaction with a print to understand dimensions when users do not have a 3D model. Users can click on the print to take dimensions that are not clearly labeled, but may impact fixturing or spacing. Users can toggle between unit measurements and annotate in comments for future reference. Also, the platform’s Vectorization and Analysis capabilities turn a PDF into a Drawing Interexchange Format (DXF) to extract complete data, improving estimating accuracy and preventing return materials authorizations.

Users can use the Annotate and Assign Tasks feature to quickly annotate PDFs to better communicate with other team members around specific content. This includes making time-stamped notes that may be easily referenced in the future, marking specific areas of prints and assigning tasks in the context of a drawing. Users can also utilize Secure External Sharing to quickly and securely share drawings with external vendors for review and quotation.

Related Content

-

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

-

Starting Small with Automation

Quick-change workholding and flexible robotic automation started this small shop on the path to success.

-

Video: Using AR for Remote Machine Tool Troubleshooting

Augmented reality can enable service engineers to help machine shops identify and possibly remedy issues with their machines remotely, perhaps eliminating the time and cost of an on-site diagnostic and maintenance visit.

.jpg;maxWidth=300;quality=90)