Sorter Inspects Over 360 Degrees

PMTS 2019: Resec System’s J198 sorter inspects the average, maximum and minimum measurements of each dimension of a part.

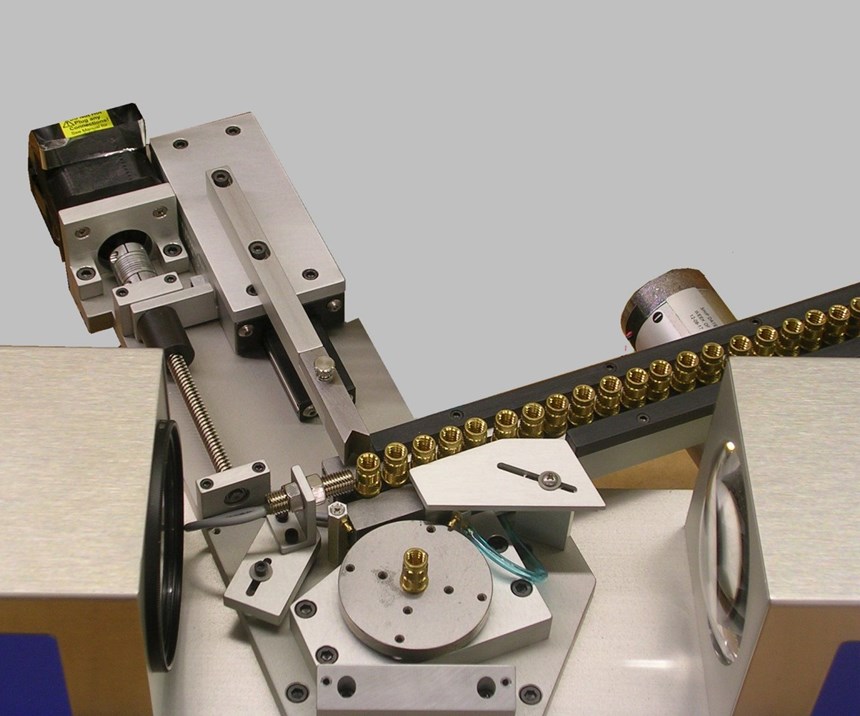

Resec System’s J198 sorter uses a rotating stage to inspect turned parts over a 360-degree rotation cycle. The average, maximum and minimum for each dimension are extracted as the part rotates, thus producing gage repeatability and reproducibility results for measurement of parts that exhibit out-of-round conditions.

In addition, the rotation is designed to enable the identification of chips, burrs and other anomalies that may only be visible in a portion of the part. Precision optics and an LED strobed lamp obtain a quality, blur-free image of the rotating part. After the dimensions have been inspected, the part is ejected into a pass or fail bin. Each part’s measurements are stored in a file and can be retrieved by an SPC application.

Related Content

-

PMTS 2023: Discovering Precision Machining Technology Under One Roof

Like Production Machining, trade shows such as PMTS enable you to discover new shopfloor equipment, technology and ideas that can help boost your shop’s efficiency and profitability.

-

Multispindle Automatic Lathe With Full System Concept

PMTS 2023: Tajmac’s Penta TMZ 518 is a five-spindle automatic lathe that features an island concept which offers the machine as a package.

-

Schaublin 302 Is Compact, High-Precision Lathe for Flexible Production

PMTS 2023: This multipurpose machine is a high-precision production lathe that features a FANUC digital control, compact size and flexibility for cost-effective, small- and large-scale production runs.

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)