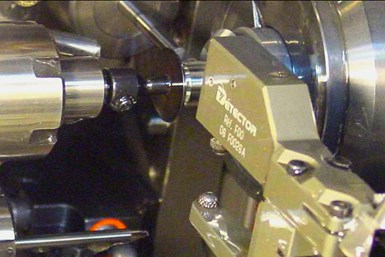

SPC Innovations' Detector Inspects, Detects in Real Time

PMTS 2023: Modular design enables gages and probes to be added or moved from machine to machine with minimal additional setup cost.

Photo Credit: SPC Innovations

SPC Innovations’ Detector ETC System is designed for real-time, in-machine part inspection and broken tool detection. The system is built on the proven effectiveness of the existing Detector line of gages, while adding electronic broken tool monitoring capabilities in one simple display, the company says.

The modular design enables gages and probes to be added or moved from machine to machine with minimal additional setup cost. The ETC System features real-time, in-machine inspection and corrective action. It has a single, intuitive industrial grade display and is compatible with all Detector gage probes and electronic broken tool detectors. The system also features bidirectional, multi-tool presence/absence sensing and is expandable to eight probes per display.

Related Content

-

The Ins and Outs of Inserts

Understanding how inserts are made provides valuable insight into how their performance can be optimized.

-

The Value of Swiss-Types Milling Rectangular Medical Parts

High-speed spindle technology was key to effective milling of small cardiac monitoring components complete on a CNC sliding-headstock machine platform instead of running them across two mills.

-

Breaking the Barriers for Small Tool Breakage Detection

This contact-free tool breakage detector, especially useful for machine tools with small tools and small workzones, offers a quick and efficient way to change out broken tools before they cause bigger problems.

.png;maxWidth=300;quality=90)