Spindle Monitoring Solution Protects CNC Spindles

PMTS 2023: This all-in-one spindle monitoring system protects CNC spindles from running unbalanced tools, aggressive cuts and crashes by offering real-time performance data.

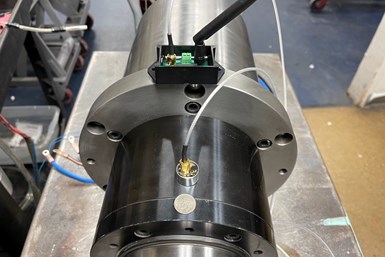

Shown here is a spindle with VibePro Tect installed, 3-Axis sensor and wireless transmitter which transmits collected data to the web app. Photo Credit: GTI Spindle

GTI Spindle Technology’s VibePro Tect is an all-in-one turnkey spindle monitoring solution. The latest iteration features banding, which is essential for triggering alarms, and adds valuable trending insights to the data monitoring process.

The sensor can be an indispensable solution for any machine tool shop’s reliability and maintenance program. It is an all-in-one spindle monitoring system that protects CNC spindles from running unbalanced tools, aggressive cuts, and crashes by offering real-time performance data. In turn, this helps prevent more severe and costly spindle repairs or replacement.

The system monitors the spindle and has a diagnostic mode for general spindle health, including bearing wear. The banding feature makes the tool even more valuable, as it could more specifically indicate what’s going on within the spindle, such as imbalance, misalignment or bearing defects. Many of these issues are inaudible to the human ear, until they have become much more serious and costly to repair.

The company say’s VibePro Tect is a comprehensive, easy-to-operate solution. After it has been installed, operator interaction is not required. The system will send a daily health report to the website for tracking. If an alarm is breached, it will send an immediate report and data of the event, including the time of the event and if any long-term damage resulted. All data is remotely accessible.

Related Content

-

The Ins and Outs of Inserts

Understanding how inserts are made provides valuable insight into how their performance can be optimized.

-

Starting Small with Automation

Quick-change workholding and flexible robotic automation started this small shop on the path to success.

-

Replaceable-Insert Spade Drill Basics, Advantages

Although solid carbide and indexable-insert drills have their place in a machine shop, replaceable-insert spade drills offer specific advantages for various holemaking operations on machining centers and lathes.

.png;maxWidth=300;quality=90)