SprutCAM Software Update Enhances Robot Support

The update includes Profile Mode for lathe operations, enabling users to now adjust the chamfer angle in profile cycle based on the 3D model.

SprutCAM Tech launches update 17.0.14 and 17.0.15 for SprutCAM X and SprutCAM X Robot, featuring more than 200 changes.

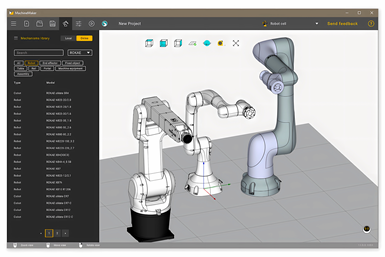

This update enhances includes added support for Kawasaki robots (BX300L model and others) in SprutCAM X Robot and MachineMaker. Additionally, support for 27 models of ROKAE robots has been added to MachineMaker. Kinematic models of these robots are now also available in the online robot library.

Additionally, the update includes Profile Mode for lathe operations enhancement. In job assignment for lathe operations, users can now adjust the chamfer angle in profile cycle based on the 3D model, an improvement from the previous limitation of only being able to change the chamfer size.

User experience enhancements include:

- Updated pop-up hints for lathe machining, engraving, pocketing and chamfer machining operations.

- Improved functioning of pinned snapshots.

- Enhanced overall performance of SprutCAM X and SprutCAM X Robot.

- New feature, which allows users to save tutorials on post processor development as an archive file, enabling offline access.

- Added Machine setup template for Swiss-type machines.

- Increased speed of machining report generation with sketch output. The generation of sketches has been optimized, significantly reducing the machining report generation time.

- Updated smart hints for lathe part off, 5D by meshes, turn takeover, 3D helical and scallop operations.

Significant improvements have been made in update 17.0.14, addressing some challenges across the software. Notably, enhancements include fixing spline handling issues and refining the operation of vectors in 6D contour tasks. The update also resolves critical bugs such as the mishandling of network licenses and the visualization of 3D models in the tool library. The software now correctly updates fixtures during rotate and shift operations and eliminates previous issues with machine node saving in MachineMaker. Additionally, it resolves a recurrent error during the trajectory calculation for cladding operations.

With update 17.0.15, SprutCAM fixed a critical error related to recalculating operations with the workpiece considered and errors when editing four- and six-axis limits for industrial robots. Importing step files no longer causes hangs, and we resolved axes collision issues in the standard project included with SprutCAM X. Errors in polar interpolation on lathes, collision avoidance options and 5D mesh operation calculations in standard projects have been fixed. We corrected bugs in various areas such as the safe surface level option for adaptive machining, tool center point (TCP) calibration app links and toolpath calculation in 6D contour operation. Additionally, issues with localization rollbacks, launching SprutCAM on Windows 7 and cutter shank operations were also resolved.

Related Content

-

Mastercam 2024 Integrates Sandvik Coromant CoroPlus Tool Library

The integrated library enables users to work faster when importing tool geometries and cutting data.

-

How to Start a Swiss Machining Department From Scratch

When Shamrock Precision needed to cut production time of its bread-and-butter parts in half, it turned to a new type of machine tool and a new CAD/CAM system. Here’s how the company succeeded despite the newness of it all.

-

The Value of CAD/CAM and Cutting Tool Manufacturers Working Together

Overall machining efficiency can be increased when software and tooling companies combine to tackle machining challenges.

.jpg;maxWidth=300;quality=90)