Steelhead’s Customizable Software Improves Shop Productivity

PMTS 2023: The software has an all-in-one dashboard that enables all employees to access targeted information applicable to their responsibilities.

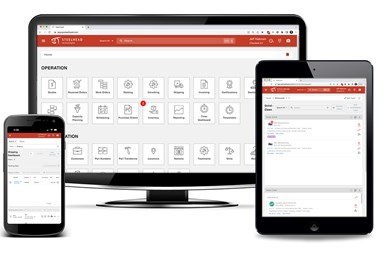

Steelhead Technologies says it offers an ultramodern software solution for managing job shops with a highly customizable, cloud-based platform that can be precisely tailored to drive data-based management. The software features an all-in-one dashboard that enables employees to access targeted information applicable to their responsibilities.

The job shop software is designed specifically for the process manufacturing industry. Created to manage production in dynamic environments, the system’s intuitive design enables operators to be trained in minutes and customers can launch the technology at their job shop within weeks for a simple, yet extremely effective, digital transformation.

The software is used in manufacturing to improve the process, profitability, productivity and quality of an entire plant by eliminating wasted time in order processing, administrative tasks and paper workflows. As job shops are looking for a way to process more parts, faster, Steelhead software can significantly save time to free up operators to get more done, reduce lead times and ultimately boost profitability, increasing the overall value of the business.

User can create an accurate quote in seconds with customized pricing algorithms. The software can also harness full production visibility and data to uncover job cost data to optimize productivity and boost profits by up to 35%. The software enables users to send quotes, add work orders, include product recipes, track the movement of parts, send packing slips and invoices, train operators, automatically generate reports and reprioritize jobs all with the tap of a finger.

Related Content

-

Compact Micro Turn-Mill for Small Precision Parts

PMTS 2023: The Spinner PD-CNC lathe can achieve high levels of precision due to its high-precision spindles, pneumatic clamping cylinders with programmable clamping force, ultraprecise ball screws, and hardened and ground sliding vibration-damping guideways.

-

Syncrex Swiss-Styles for Fast Tool Setup, Easy Programming

PMTS 2023: The Mazak Syncrex series comes in four bar capacities, ranging from 20 to 38 mm, and is available in 7-, 8- and 9-axis configurations as well as a 9-axis model with full B-axis contouring.

-

Get to Know the PMPA at PMTS 2023

The Precision Machining Technology Show provides the chance to see what membership in the Precision Machined Products Association offers at the association’s co-located National Technical Conference.

.jpg;maxWidth=300;quality=90)