Transfer Machine Features Independent Turning Cell

Isolated turning cell within transfer machine is free of the drive and machining factors that affect the other stations.

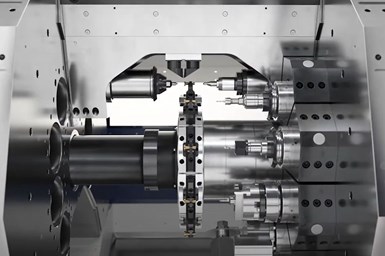

Winema says its PTC (precision turning cell) for its RV10 Flexmaster transfer machine enables users to machine the entire external contour of a workpiece without positioning errors to micron-level accuracies. The PTC is integrated in the machine as a disconnected turning cell and it is free of the drive and machining factors that affect the other stations. It is said to provide high concentricity precision with internal and external turning.

As a closed, vibration-damped cast design, the PTC can transfer the workpiece into an independent coordinate system where it can perform a turning process in isolation. When turning between centers, accurate concentricity remains consistent down the entire length of the workpiece. If a workpiece is held in a collet chuck by the PTC, tight positional tolerances can also be maintained between external and internal contours. The PTC features two turning tools with Capto interfaces and three PTCs can be integrated into each machine.

Related Content

-

CNC Rotary Transfer Machine Offers AI-Learning, Chipbreaking

Hydromat’s Force CNC Rotary Transfer Machine comes equipped with Force 50/150 tool spindle units, which are FANUC-controlled and offer advanced technology for AI-learning and chipbreaking functions.

-

Independent Turning Cell Enables High Concentricity Precision

PMTS 2023: The RV 10 Flexmaster rotary transfer machine’s precision turning cell (PTC) is integrated in the machine as a disconnected turning cell and is free of the drive and machining factors that affect the other stations.

-

Edge Technologies Bar Feeding Solutions Support Range of Production Environments

IMTS 2024: Edge Technologies' product showcase includes a magazine feeder and short loader, as well as a bar feeder, pusher and separation system.

.jpg;maxWidth=300;quality=90)