Twin-ATC B-Axis Turn/Mill

Methods Machine Tools’ Nakamura-Tome Super NTMX multitasking turn-mill offers dual 24-tool ATC magazines. Full five-axis milling capability via a Fanuc 31i-A5 control is said to provide high precision and accuracy for manufacturing complex contoured components in large or small volumes for the medical, aerospace and similar industries.

Methods Machine Tools’ Nakamura-Tome Super NTMX multitasking turn-mill offers dual 24-tool ATC magazines. Full five-axis milling capability via a Fanuc 31i-A5 control is said to provide high precision and accuracy for manufacturing complex contoured components in large or small volumes for the medical, aerospace and similar industries.

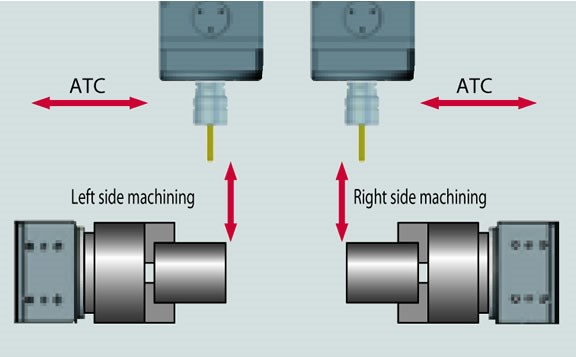

The dual ATC magazines enable tools to be separated from a central magazine and placed on the left or right spindle, depending on where they will be used. If 24 tools are insufficient for operations on one side, or if the operator wants to use the same tool for similar operations on both spindles, tools from the left magazine may be used on the right spindle or the right magazine on the left spindle.

Storing left- or right-side spindle cutting tools respectively on the left or right side ATC magazine enables tool change on the nearest magazine. For simplified operations, the machine features easy access and fast setup via the front location of the ATC magazines and an easy-to-operate tool spindle, the company says. To increase tool changing speed, the inserts can be changed without stopping the machine. When running in auto mode, either tool magazine can be rotated in manual mode and tools can be loaded for the next setup. It is also possible to use one magazine for one setup and keep the second magazine for the next setup. In that case, the setup time can be reduced nearly to zero.

The auto-sort function reads the machining program and automatically rearranges the tools to be used in the process between magazines. Tools are moved from the left or right side magazine, and at the same time, are rearranged in accordance with the program. By using this function during a setup change, tools are rearranged quickly, and the shortest distance ATC can be achieved.

The machine includes a lower turret with 12 stations and ½ index capabilities for a total of 24 available tools. The turret enables turning, drilling, boring, grooving and threading operations. The ATC magazines offer a maximum capacity of 48 tools. Spindle speeds range to 5,000 rpm at 15/10 hp. Other features include a 6" (150-mm) chuck and 2" (51-mm) bar capacity. A 10/5-hp tool spindle ranges in speed to 12,000 rpm. The distance between the spindles is 38.58" (980 mm) with a maximum turning diameter of 7.67" (195 mm) and a maximum turning length of 30.70" (780 mm). The system is offered in a 102 sq. ft. footprint with dimensions of 112.4" × 132" × 106.2" (2,855 × 3,353 × 2,697 mm).

Although it is designed as a floorspace-saving machine, the Super NTMX has a wide working range. The upper or lower unit can be freely programmed to work on either of the two spindles, maximizing process flexibility. Additionally, part supporting such as servo-controlled center support and others contribute to one-hit machining from bar work, shaft work or forgings.

Related Content

-

5-Axis Machining Centers Transform Medical Swiss Shop

Traditionally a Swiss machine shop, Swiss Precision Machining Inc. discovers a five-axis machining center that has led the company to substantial growth. (Includes video.)

-

When a CNC Turn-Mill Doesn’t Turn

A shop in Big Sky Country uses a B-axis multitasking machine to produce complex, prismatic medical parts that require no turning complete from barstock.

-

Video: Why a Production Machine Shop Started a Baseball Bat Company

A 153-year-old manufacturer of precision, metal pins recently started a side business creating custom wooden baseball bats. The reasoning behind establishing this new company is intriguing, as is how it has helped create a stronger bond with the local community.

.jpg;maxWidth=300;quality=90)