Wire EDM Machine Enhanced With High Precision, Intelligent Interface, Service Support

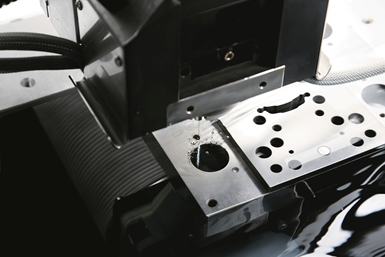

IMTS 2022: GF Machining Solutions’ CUT X 500 and CUT P 350 Pro wire-cutting EDM machines offer heightened accuracy, precision and productivity.

Photo Credit: GF Machining Solutions

GF Machining Solutions’ latest EDM integrated problem-solving solutions include the Cut X 500 and Cut P 350 Pro wire-cutting EDM machines for precision part generation. To maximize machine tool value and competitive readiness, GF Machining’s subscription-based Success Packs are said to feature comprehensive customer support as well as digital services that add connectivity for remote machine monitoring and troubleshooting no matter the location.

With Intelligent Power Generator (IPG) technology, the Cut P 350 Pro is said to deliver surface finishes as smooth as Ra 0.08 µm and heightens accuracy with integrated thermal regulation that maintains temperature at ±0.2°C. To accommodate heavy workpieces, the machine’s Quadrax mechanical system is said to keep the table, work tank and dielectric liquid stable.

In addition, the Cut P 350 Pro and Cut X 500’s Uniqua human/machine interface (HMI) is said to deliver optimal functionality and ergonomics in a 19" vertical touchscreen, full keyboard and mouse. A variety of automation options add to the machine’s scalable flexibility, with optimized production for electronics, automotive, medical, and mold and die manufacturers through more than 600 preprogrammed cutting processes.

According to GF Machining, the AgieCharmilles Cut X series holds extreme accuracies in machining positioning and pitch. Developed to provide high precision and thermal stability in large runs of complex components (including stamping tools, multicavity molds and micro components), the Cut X 500 and all other Cut X machines feature adapted mechanical structures, dedicated machine calibration and testing to deliver pitch accuracy as low as 1.0 µm.

High-precision axes, short measurement loops, dual measurement on all axes, consistent isolation of the EDM area from heat sources and submerged working areas optimize conditions for micro applications, the company says. Two-spool Automatic Wire Changer technology and an onboard Job Management System help further reduce processing time and simplify job prioritization.

Related Content

-

Starting Small with Automation

Quick-change workholding and flexible robotic automation started this small shop on the path to success.

-

Automation in the Alps: Studer AG Unveils New Grinding Concepts

Studer AG, member company of United Grinding, held its annual press conference at its Swiss Alps location earlier this month to announce its new automatic loaders to accompany its existing grinding machines as well as other offerings and automation features.

-

High-Production Multitasking Becoming More Flexible

Rotary transfer machines remain well-suited for high-volume production, but are now more accommodating to smaller batch sizes.