CAD/CAM

Software User Interface Updates

The company has revamped the PartMaker user interface, improved capabilities for programming directly on solid models and the ability to automatically generate descriptive and visual setup information. The user interface features easy-to-use, user-configurable toolbars. Existing icons have been recast to make them easier to understand, the company says.

Read MoreMultitasking with Enhanced Lathe Features

GibbsCAM MTM (multitask machining) now includes lathe features that are said to provide more efficiency through tool control and take advantage of newer high-tech cutting tools that turn harder materials and machine smoother surfaces.

Read MoreCAM Software Offers Ease of Use

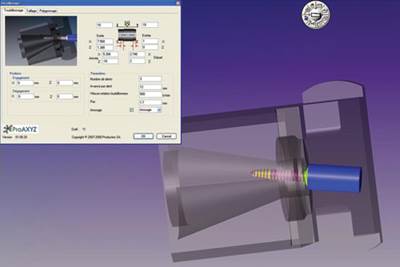

The Esprit 2009 CAM software is designed to save time and money by importing solid models, recognizing features on those models and automatically drawing options from a database of machining practices for the machining of those specific features and for a range of machine types. The KnowledgeBase user interface has been centralized to make it easier to manage all of the data in the database, the company says. The single, consistent user interface allows users to access all the data from one central location, such as the processes, materials and cutting tools, and context-sensitive commands are available with a right-click of the mouse.

Read MoreCAM For Multitasking Operations

While still running a few different CAM systems in the shop, this manufacturer of aerospace and oil and gas industry components has implemented what it sees as the ideal package for programming its multitasking work.

WatchProgramming Lathes: Eliminate Cutting Air On The Second Pass

Cutting air benefits no one. Eliminate it in the programming department.

Read MoreSoftware And CNC Package Improves Production By 15 Percent

With a unique part program software suite onboard a powerful CNC, one shop has found it’s producing more and better parts much faster on a recently acquired turning center.

Read MoreThe Growing Power Of 3D

Some recent events have opened what I consider for me a new dimension in manufacturing. At Delcam's recent Technical Summit at Methods Machine Tools in Sudbury, Massachusetts, I got an in-depth look at the company’s extensive range of CAD/CAM solutions. While I've long enjoyed seeing new developments in such pr

Read MoreShop Races Ahead Using CAM Software

In 1998, race car driver Robby Gordon wanted to make his own racing components, so with partners Larry Novak and Larry Kaford, he opened SR Machining in Anaheim, California. CNC Programmer Warren Myers arrived the first day, an hour before the shop’s first machine, a two-axis lathe. Because race car parts were insufficient to keep the lathe running at full capacity, the shop split its time evenly between racing components and parts for customers.

Read MoreFast Prototype To Production

When a shop designs, develops, manufactures and markets a range of high-accuracy, high-volume components, it must depend on high-speed machining capabilities incorporated in its machines’ CAD/CAM software. Oscor Inc.

Read More