Cutting Tools

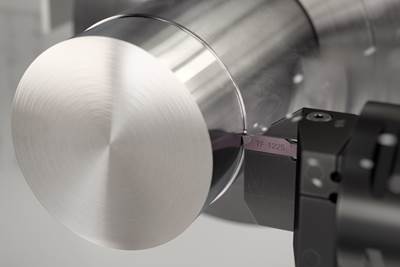

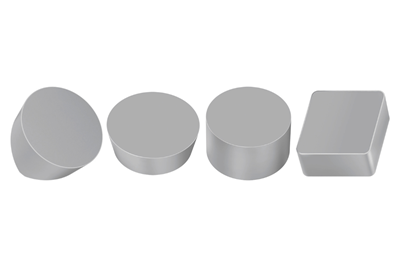

The Ins and Outs of Inserts

Understanding how inserts are made provides valuable insight into how their performance can be optimized.

Read MoreTungaloy Fine-Boring System Increases Machine Utilization

The latest KKH cartridge modules for the SwissBore digital fine boring tool system is designed to provide maximum machine utilizations with minimum measuring, setup and tool changing time.

Read MoreSandvik Coromant Grooving Tool Provides Stable Performance

The CoroCut 2 system features an improved clamping finger design, which offers a higher clamping force and better side stability.

Read MoreReaming as an Alternative to Single-Point Boring

Using slip yokes as an example, reaming through holes can be more efficient and effective than single-point boring operations.

Read MorePrecision Machining Technology Review: December 2023

Production Machining’s December 2023 technology showcase includes some of the latest technology from Sandvik Coromant, Nikon Metrology, The L.S. Starrett Co., Walter USA, Kennametal and SolidCAM.

Read MoreWalter Ceramic Inserts Enable Efficient Turning, Milling

Suitable turning and milling applications of the WIS30 ceramic grade include roughing, semi-finishing and finishing, as well as interrupted cuts.

Read MoreThe Value of Tool Monitoring on Rotary Transfer Machines

By using a tool monitoring system, shops can save costs associated with machine maintenance and downtime for tool changes while increasing cutting performance.

Read MoreNew Cutting Tool Technology Discovered at Paul Horn Open House

During a tour of the company’s campus in Tubingen, Germany, I and more than 3,000+ others were introduced to a number of new advances the company has made in cutting tool technology particularly as it relates to the medical industry.

WatchThe Value of CAD/CAM and Cutting Tool Manufacturers Working Together

Overall machining efficiency can be increased when software and tooling companies combine to tackle machining challenges.

Read MoreSandvik Coromant Turning Grade Enables High-Feed Roughing

The GC4405 steel turning grade features a new carbide substrate with an optimized microstructure, which reduces plastic deformation in high-feed applications.

Read More

.png;maxWidth=300;quality=90)